OEM & Supplier of Mineral Processing Equipment

Leading designers and suppliers of mineral process equipment and solutions.

We strive to uphold the highest quality standards, focusing on the design and manufacturing of mining and mineral processing equipment. We also offer in-house project management across the industry as another leading focus, allowing us to ensure nothing but the best for our clients.

Our entire MPT equipment range is manufactured locally, supporting the local economy and Proudly South African. Also supporting local engineering services to our clients, that is cost-effective and accessible.

All our equipment is expertly designed and sized to meet the metallurgical processing requirements of all commodities found in the mining and minerals sector. With the advantage of an extensive fabrication, machining & assembly facility, we reduce on-site risk by fully assembling & test running all equipment in-house.

Enlisting the expertise of specialists across the board, we have appointed the highest qualified personnel in every sector the industry calls for. From project management, mineral process engineering and mechanical engineering to manufacturing, quality control, delivery and support, we ensure the best of the best.

Currently, our staff comprises just under a hundred dedicated members, ensuring continuous support and backup of the products we supply.

MechProTech’s quality management system is certified by TÜV SÜD according to ISO 9001, providing world-class equipment and services to match. With an extensive fabrication and machining facility, we have reduced on-site risk by fully assembling and test-running all equipment in-house.

Our workshop is an undercover area of 2500m², equipped to handle and process 60 tons of OEM fabricated equipment monthly. This space is furnished with overhead cranes, both a 5-ton and 15-ton, as well as two 30 tons with a 12m under-hook.

To ensure the highest standard of quality in the OEM equipment we supply, there is also an in-house machine shop and assembly workshop. Adjacent to this workshop is a laydown area; both spaces are an impressive 1200 m².

All the machines are operated by our in-house staff, who run the facility day-to-day. This allows us to seamlessly control production quality at all times, meeting our deadlines and customer requirements on time. The 3.4-hectare manufacturing complex caters for complete in-house fabrication, machining and painting facilities on-site.

OEM

We are Original Equipment Manufacturers We design and supply mineral process equipment and solutions.

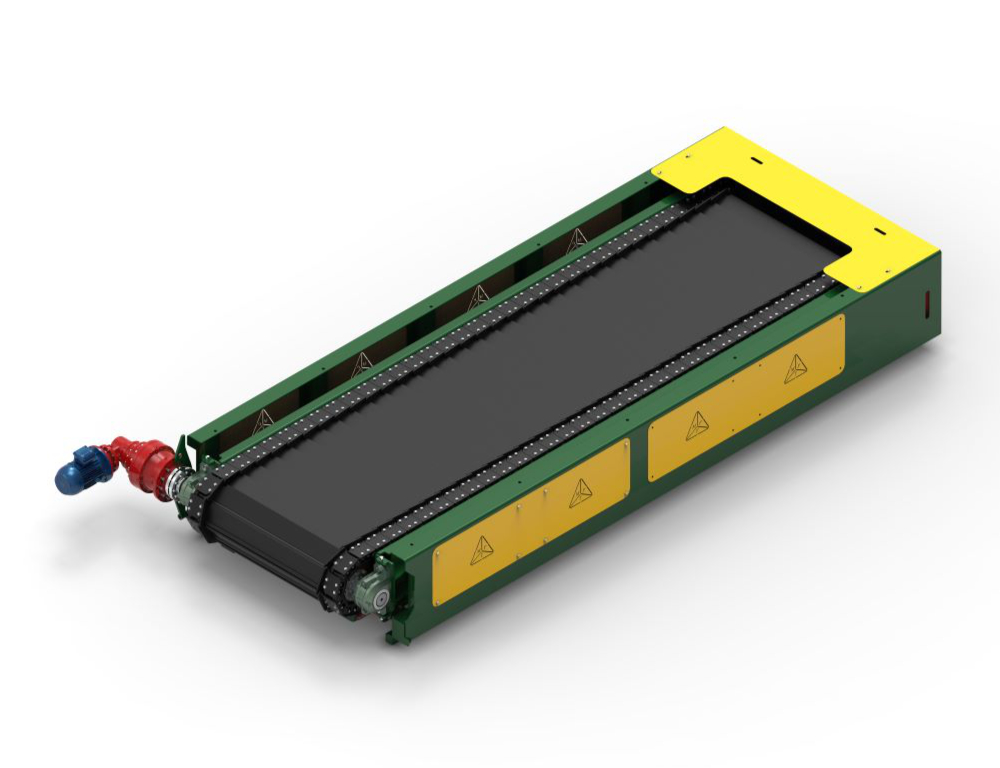

High Performance

Easily adjust stroke and speed to optimize performance and increase efficiency.

Maintenance Friendly

Convenient access to replaceable parts and high availability of support rollers, bearings ,chains and sprockets.

Durable Designs

Robust designs which are built to last and reduce the need for maintenance.

Mining Products

The robust South African modular design is an essential part of MechProTech’s success.

Get in Touch With Us Today!

We understand the unique challenges of this industry and are dedicated to helping you overcome them. Contact us today to learn how we can help you enhance your mining operations and achieve your business objectives.

About Us

MechProTech (Pty) Ltd is an Original Equipment Manufacturer (OEM). Based in Benoni, Johannesburg, we are a proudly South African manufacturer and supplier of mining & processing equipment.

Founded in 1998 by Darrel Tonkin, MechProTech continues to supply the industry with innovation as the driving force. With over 25 years of experience, MechProTech is a leading designer and supplier of mineral process equipment and solutions.

Today, we employ some of the best people in the mineral processing industry, ensuring continued support and backup of the products we supply.

Some Past Projects

Effectively developed and implemented on process plants all around the globe.

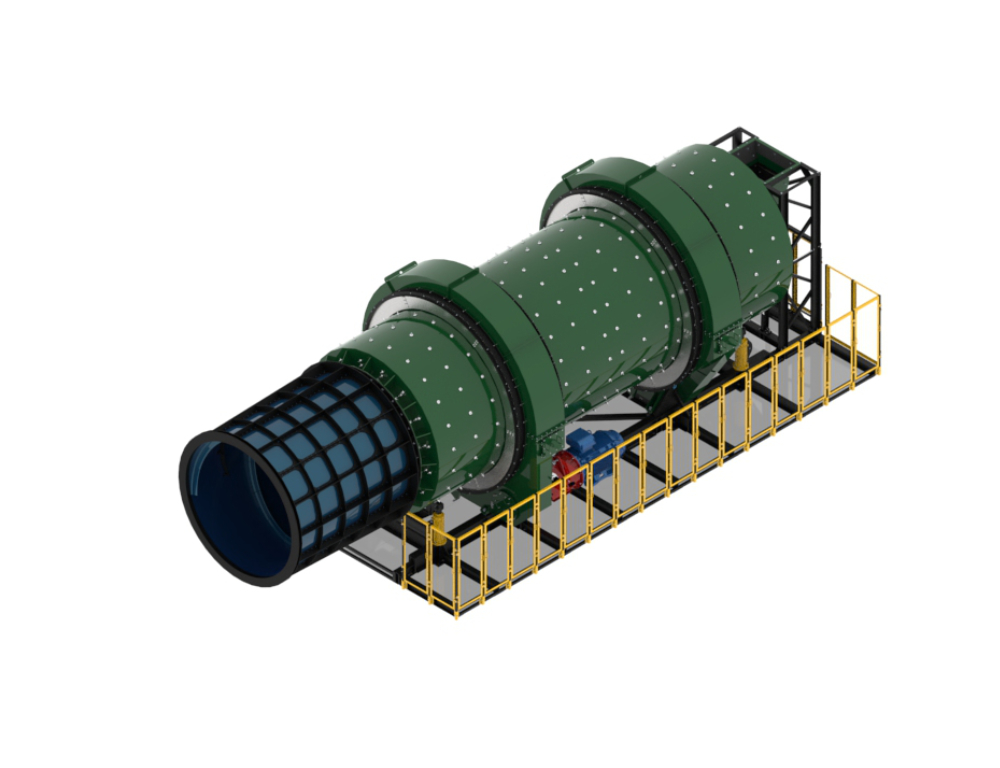

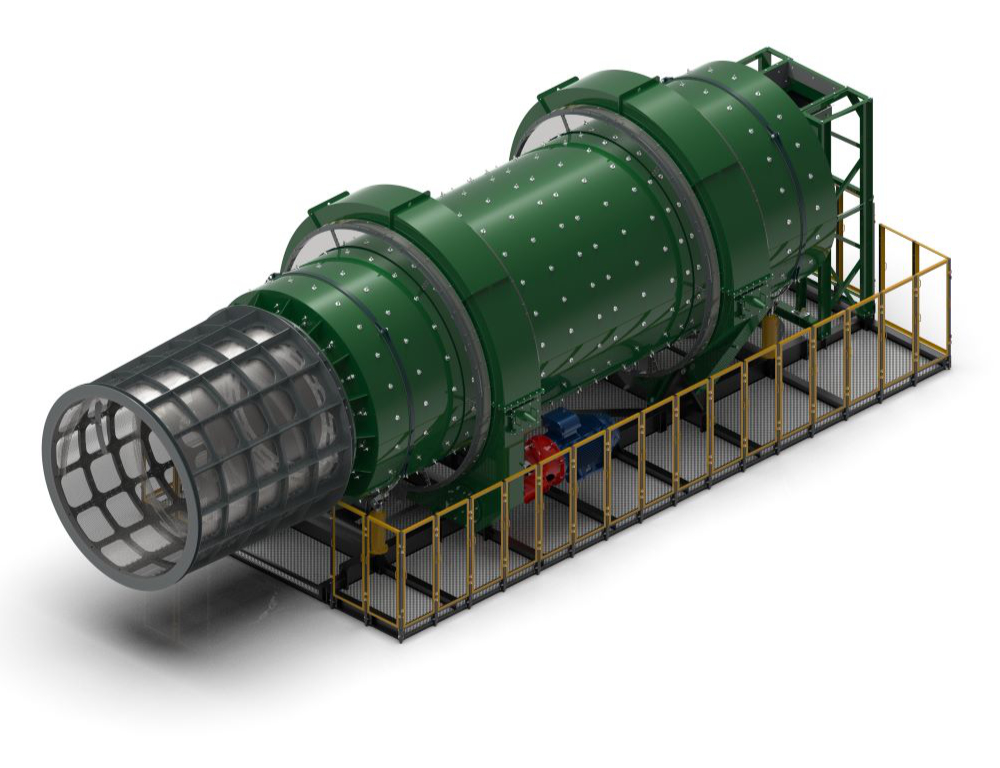

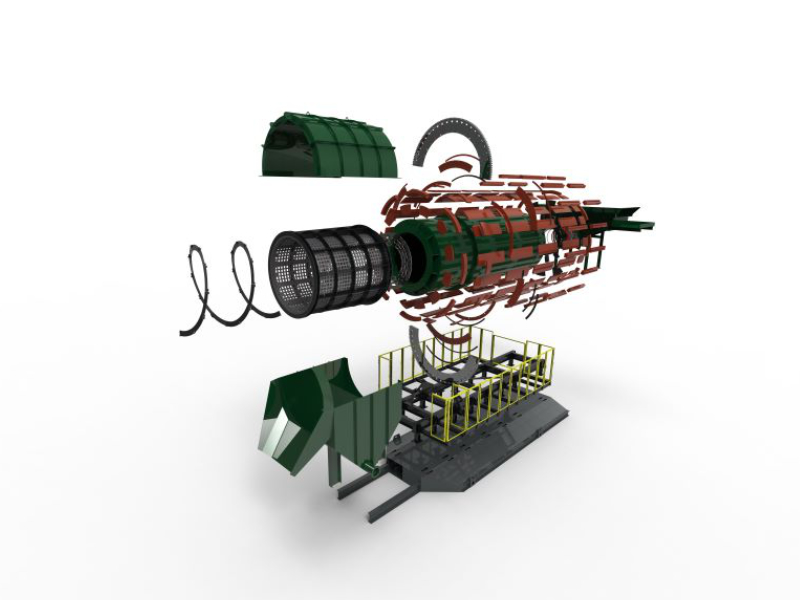

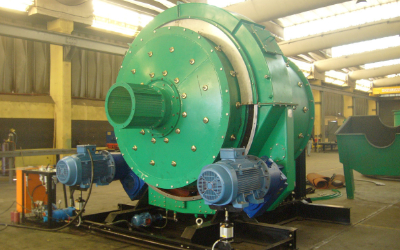

TITAN Ball Mill

- Commissioned: September 2018

- Location: Western Cape

7 t/h girth gear driven Ball Mill running on hydrodynamic vesconite bearing system. 60 kW installed, self-aligned drive on modular frame, transported as complete assembly.

Floatation Plant

- Completed: May 2018

- Destination: Zimbabwe

MPT Float Cells: 9 altogether of 3 banks of 3 float cells each of 340 liters, (40min retention time) with 1.5kw attrition and frothing elements. Mill and float plant modularized in a standard 40ft container.

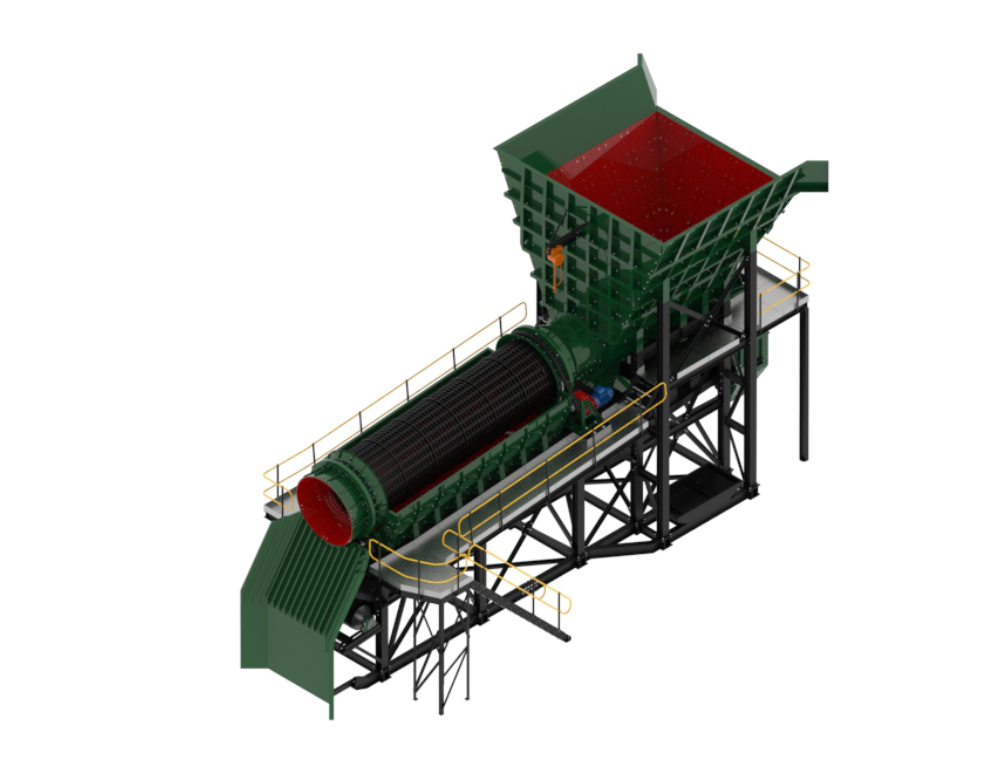

Wash Plant

- Location: Gabon – Okandji Nouvelle Gabon Mining & Aswan Mining.

- Commissioned 4 January 2019.

Screening and Scrubbing wash plant. Includes Trommel screen, crusher, scrubber, double deck vibrating screen, conveyors, cyclone and pumps. Product: +8mm; – 70mm lumby manganese [~25 t/h] -8mm; +1mm fine washed manganese product [~23 t/h].

TITAN Ball Mill

- Commissioned: September 2018

- Location: Western Cape

7 t/h girth gear driven Ball Mill running on hydrodynamic vesconite bearing system. 60 kW installed, self-aligned drive on modular frame, transported as complete assembly.

Floatation Plant

- Completed: May 2018

- Destination: Zimbabwe

MPT Float Cells: 9 altogether of 3 banks of 3 float cells each of 340 liters, (40min retention time) with 1.5kw attrition and frothing elements. Mill and float plant modularized in a standard 40ft container.

Wash Plant

- Location: Gabon – Okandji Nouvelle Gabon Mining & Aswan Mining.

- Commissioned 4 January 2019.

Screening and Scrubbing wash plant. Includes Trommel screen, crusher, scrubber, double deck vibrating screen, conveyors, cyclone and pumps. Product: +8mm; – 70mm lumby manganese [~25 t/h] -8mm; +1mm fine washed manganese product [~23 t/h].

Contact Us

Leading designers and suppliers of mineral process equipment and solutions.

Send us a message

"*" indicates required fields