After Sales

Spare Parts

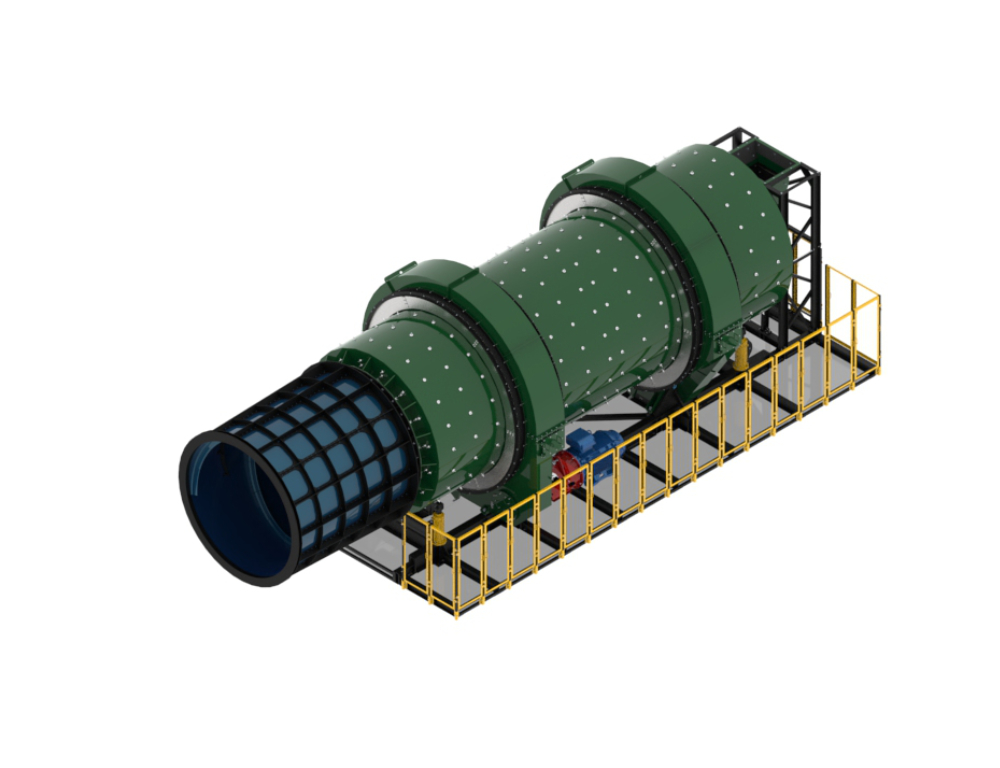

MechProTech Mill and Scrubber Spares:

With our extensive technical knowledge in servicing, manufacturing, and designing comminution components. Mechprotech offers all spare parts for not only its own OEM equipment but also that of equipment already existing in the mining operation which includes:

- Girth gears and pinions

- Shells and Trunnion Ends

- Bearings and Bearing housings.

- Trunnions

- Liners

- Drive Units

Get in Touch With Us Today!

We understand the unique challenges of this industry and are dedicated to helping you overcome them. Contact us today to learn how we can help you enhance your mining operations and achieve your business objectives.

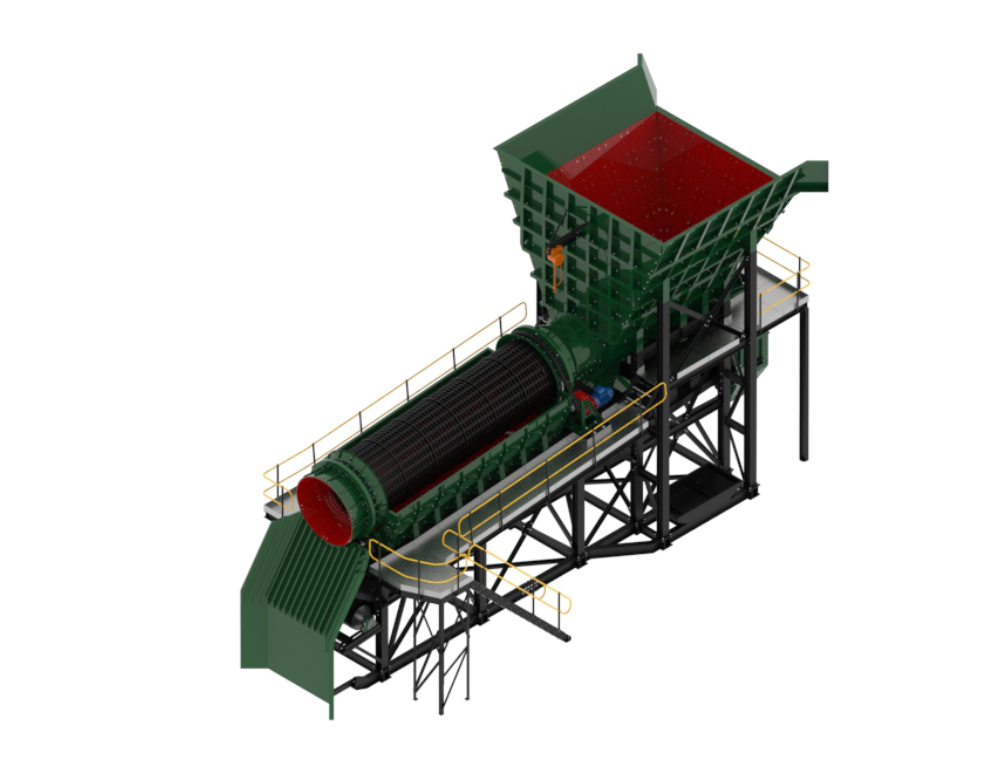

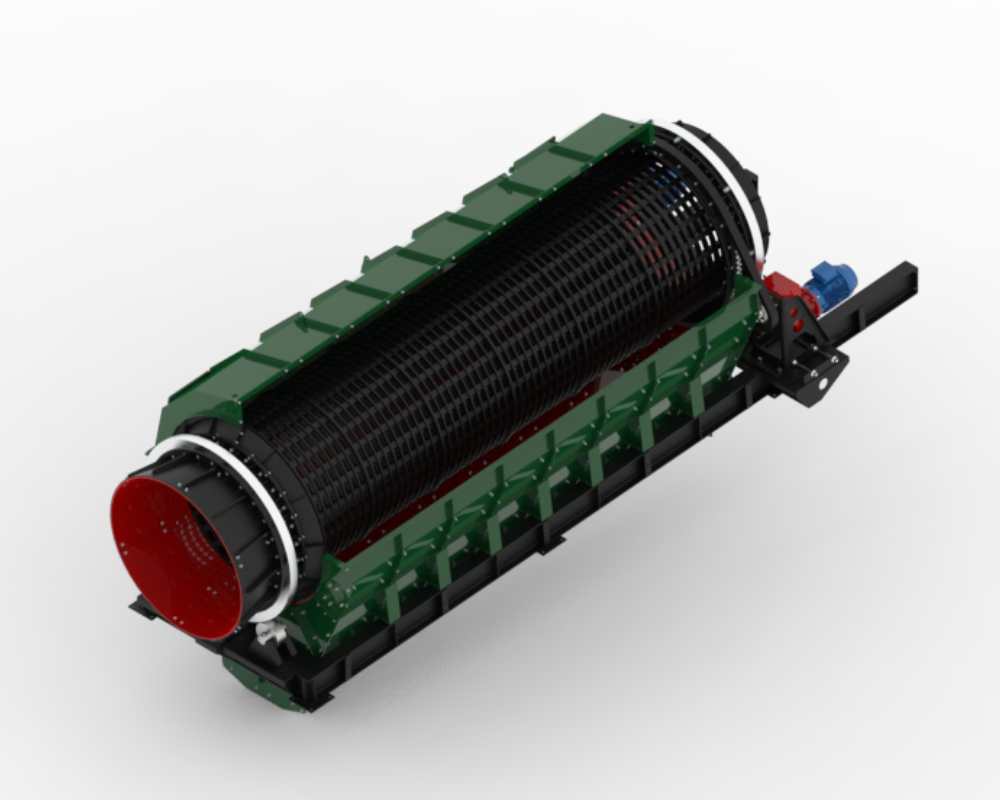

MechProTech Barrel screens and Barrel Breaker:

MPT offers spare parts for all OEM supplied equipment as well as existing site equipment. Our rotating barrel screens are subject to wear and tear while providing great performance. You can rely on MechProTech to enhance your machine’s efficiency and uphold uninterrupted productivity with the seamless installation of wear parts which include :

- Barrels

- Drive wheels

- Thrust rollers.

- Drive chains and pulleys

- Wire mesh

- Sprockets

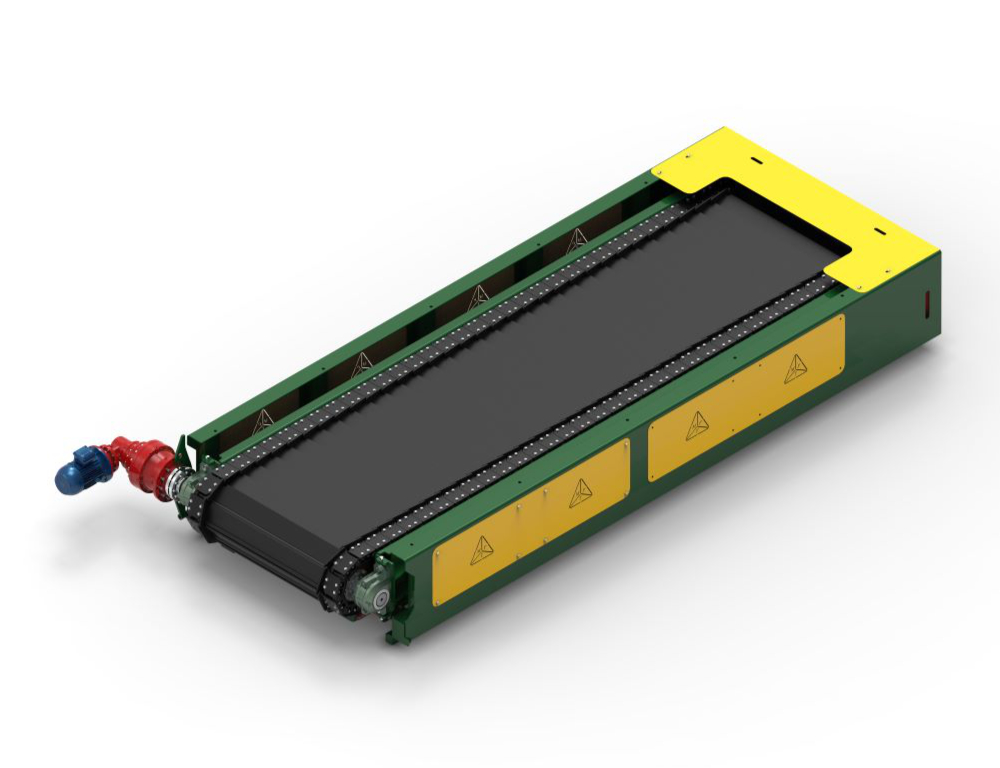

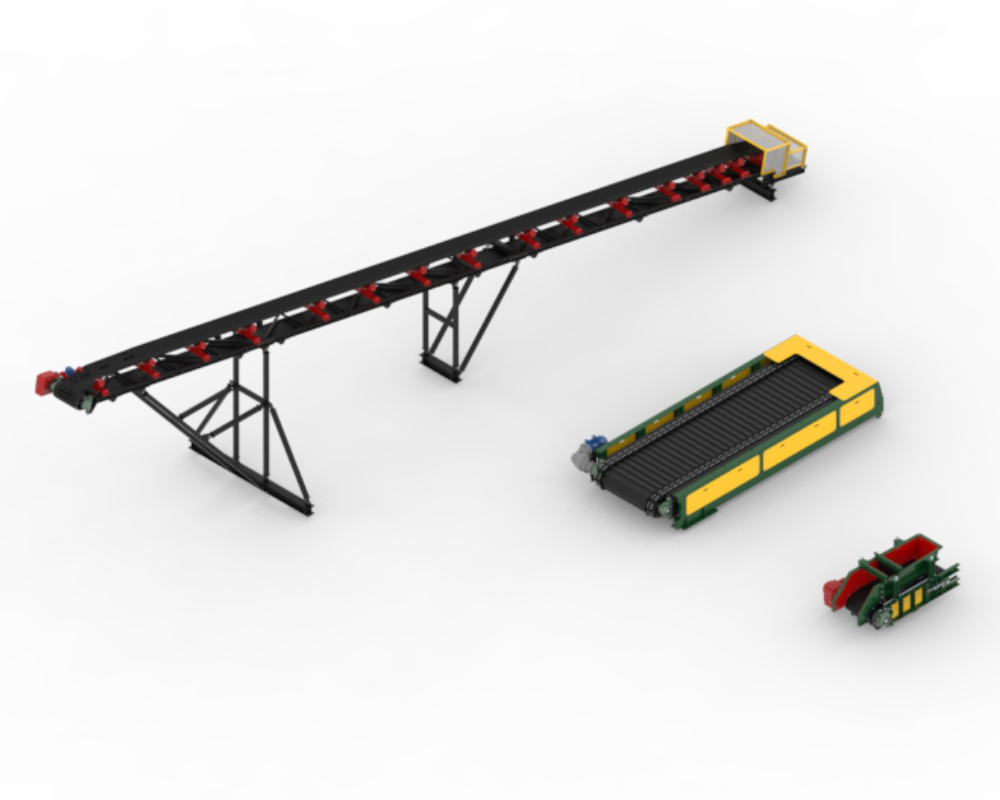

Materials Handling

At Mechprotech, we understand the importance of maximizing the efficiency and longevity of your materials handling equipment. With our expertise and resources, we offer you the opportunity to

upgrade or refurbish your existing materials handling systems that prioritizes safety and sustainability.

- Conveyor belts

- Conveyor rollers and pulleys

- Apron feeder slats

- Pulley lagging

- Belt scrapers

- Splicing kits

- Drives

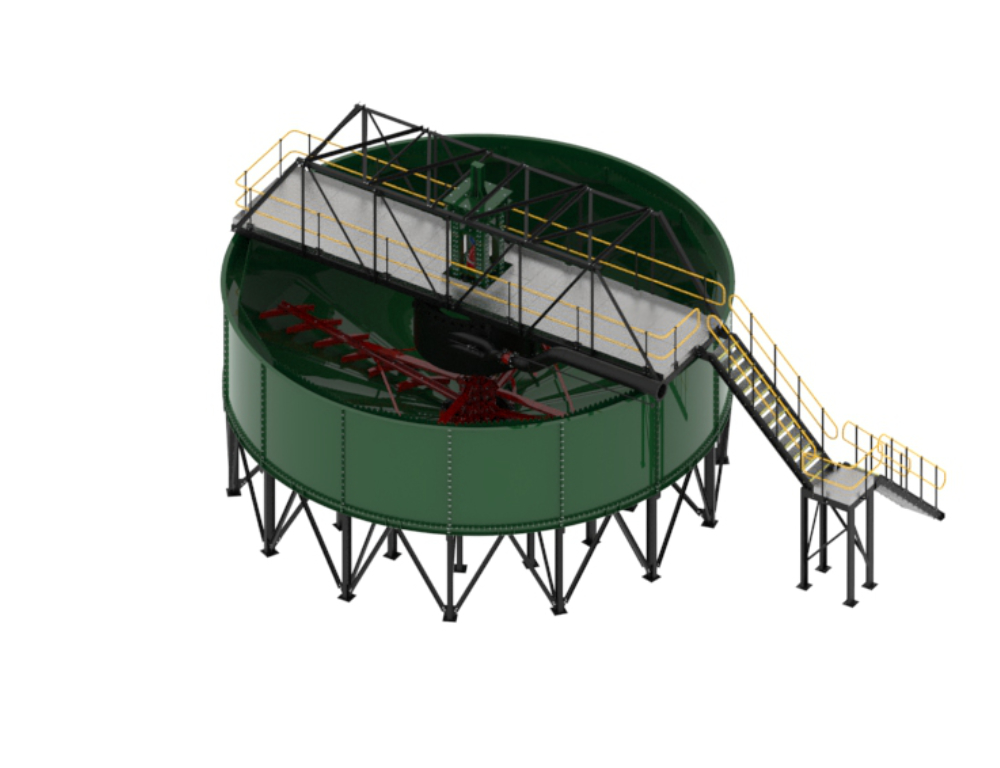

Refurbishments

Breakdowns of components, and unanticipated inefficiencies can all result in costly downtime to your mining operations Outdated, unproductive, or broken equipment might be restored and reconditioned to save money for new machinery. This method is not only more sustainable and cost-effective, but it may also assist to decrease downtime through maintaining equipment up to date and swiftly addressing faults. Indeed, extending the life of your mining equipment may boost the return of your investment while additionally preventing workers from having to learn how to operate new, unfamiliar equipment. Mechprotech’s experience spans a wide spectrum of industrial equipment, and we specialize in modernizing and repairing equipment in a variety of industries. Our thorough refurbishing process provides better production, less downtime, increased efficiency, and improved operational safety. |

Contact Us

Leading designers and suppliers of mineral process equipment and solutions.

Send us a message

"*" indicates required fields