Scrubbers

Autogenous Scrubbers

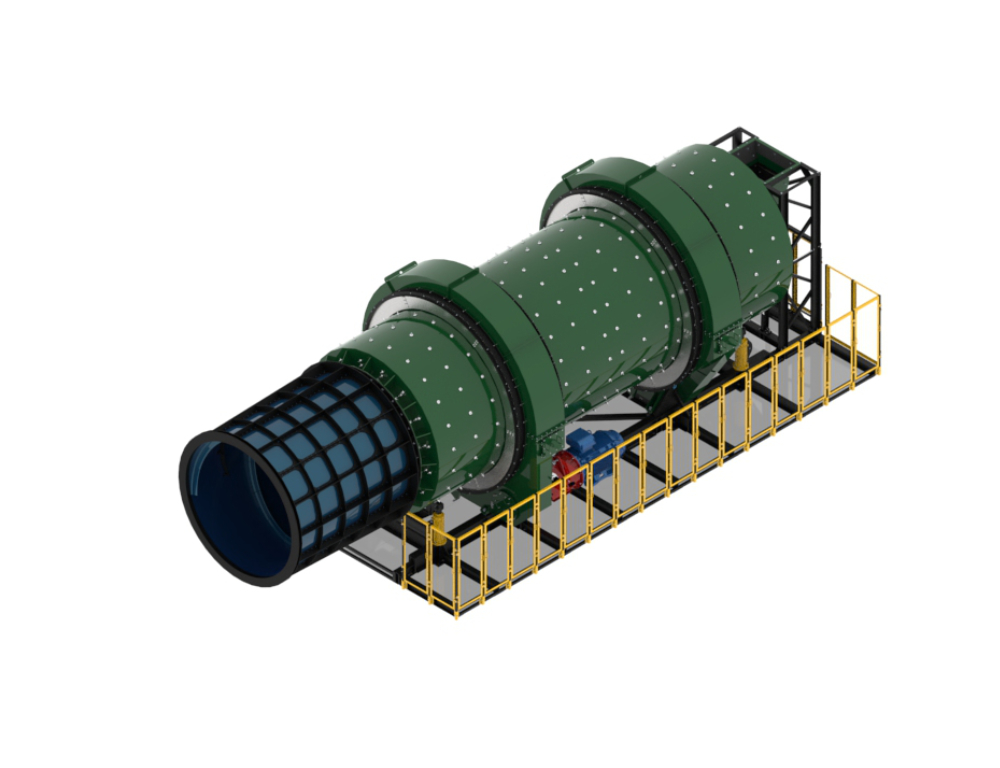

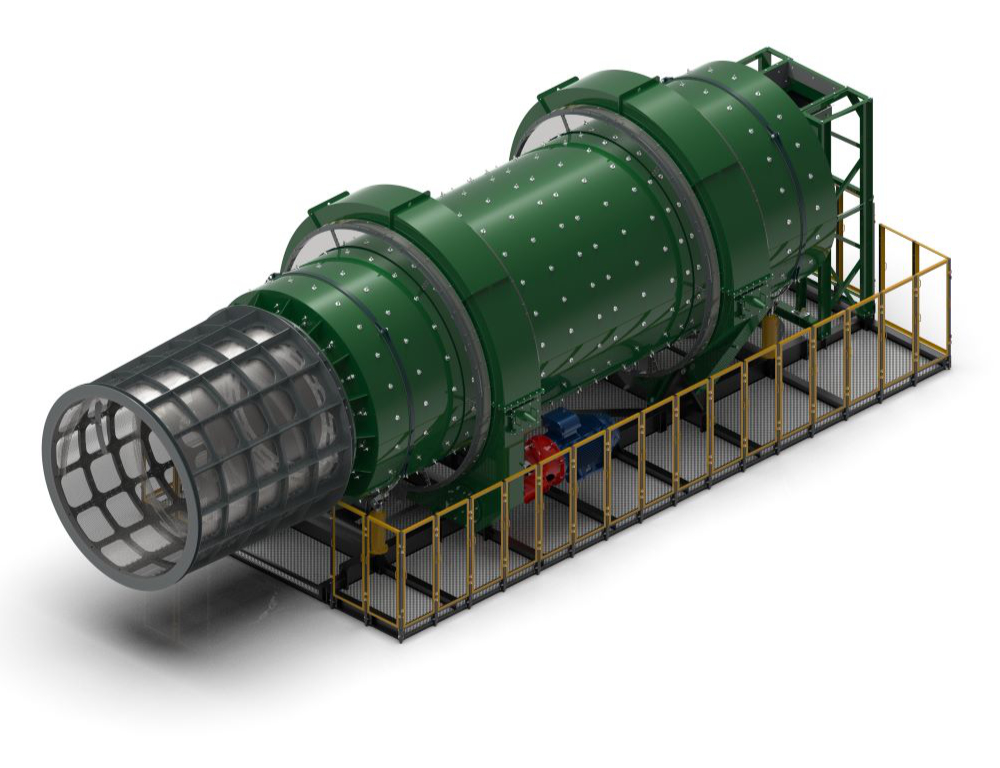

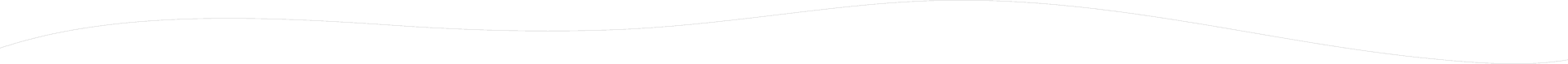

The TITAN GDS is fixed on a rigid, heavy-duty steel base frame with safety guards around rotating equipment.

The shell is supported by two 90-degree hydrostatic bearings with an oil lubrication station controlling and filtering the oil between the drive housing bearing and the station. All temperatures and pressure are measured and used to control the operation of the scrubber.

The optional design includes idler supported roller carriage, which replaces the idler-bearing housing in supporting the scrubber at the feed end. The polyurethane-designed rollers only support vertical loaded and thus have limited wear due to the fact they don’t handle the torsion loads of regular tyre-driven scrubbers.

Mechprotech’s advanced thermos-polymer hydrostatic bearing and drive arrangement, designed exclusively by our team, empowers us to manufacture machines in record time. Before dispatching to the site, our mechanical shop rigorously tests each device. When transport conditions allow, we can deliver the machine fully assembled to the site. Consequently, this significantly reduces site erection times and expedites the commissioning process, leading to faster plant production. The ingenious design necessitates a simple civil foundation since minimal mechanical forces need to be transferred from the drive train to the scrubber girth gear. With all loads being vertical, they can be adequately supported by a thickened civil foundation. As a result, there is a direct cost-saving in terms of the scrubber’s capital expenditure.

The design also allows us to skid mount our units and install them on a self-driven hydraulic track system.

Titan GDS Design

The TITAN Gear Driven Scrubber(GDS) is designed to accommodate either a Bellmouth Discharge or a Discharge Trommel, with a retention grate plate that enables a charge of competent material to be retained, resulting in high-efficiency scrubbing. The grate increases competent charge by up to plus 30%. Our product is offered with a hydraulic jack maintenance system that enables customers to service and inspect the machine without using a mobile crane or expensive overhead crane installations.

Get in Touch With Us Today!

We understand the unique challenges of this industry and are dedicated to helping you overcome them. Contact us today to learn how we can help you enhance your mining operations and achieve your business objectives.

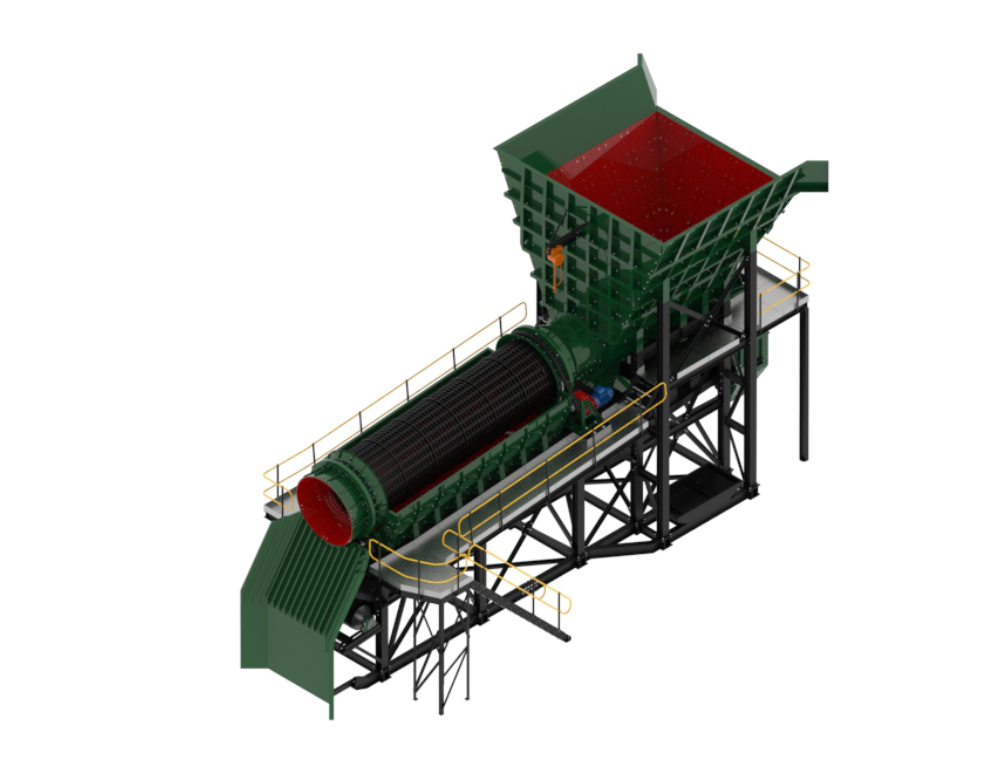

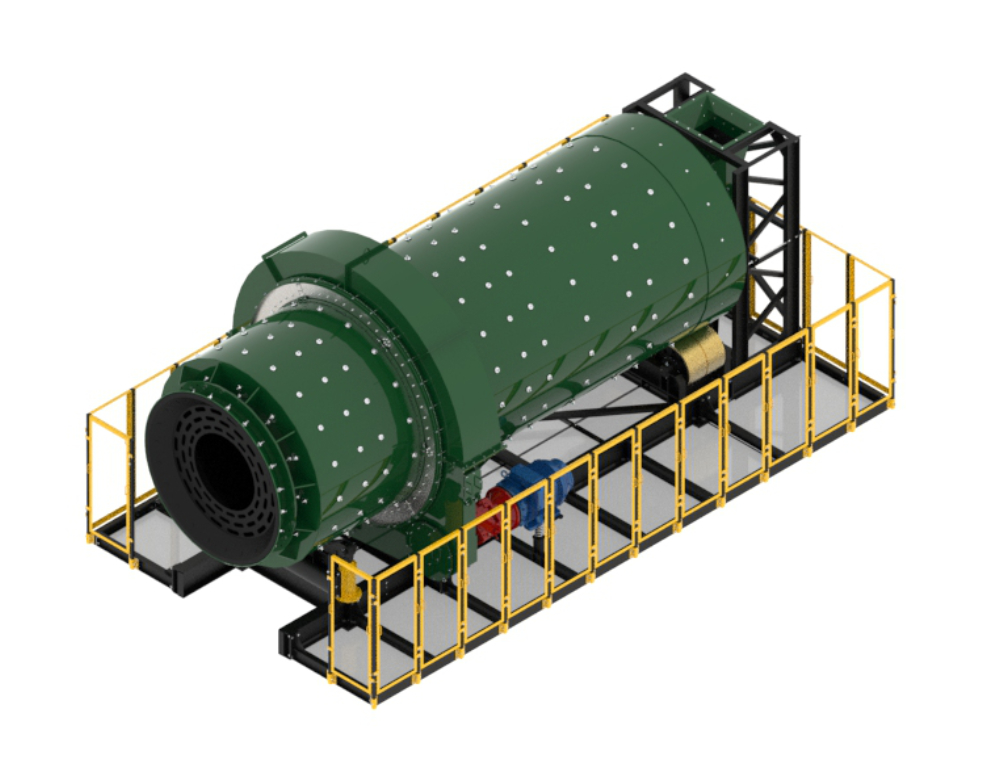

Complete Skid Mounted Circuits

The TITAN ORE SCRUBBER is a modular MechProTech OEM product design which includes feed chutes adapted for the conveyor feed option and a lobster-back inlet chute with a freshwater flange feed port. The inlet mechanical seal technology allows for high feed rates into the scrubber and limits spillage. An alternative option is Flange Pipe feed with an integrated rubber seal and flush water.

It is designed to run on a lubricated girth gear to pinion system using two off IP65 premium efficiency electric motors, each directly coupled to an inline helical gearbox. The double pinion and girth gear drive allow the unit to run in either direction, maximising the life of the Proprietary Combaflex® Rubber liners and the girth gear and pinions.

Contact us

Leading designers and suppliers of mineral process equipment and solutions.

Send us a message

"*" indicates required fields