Screens

Vibrating Screens

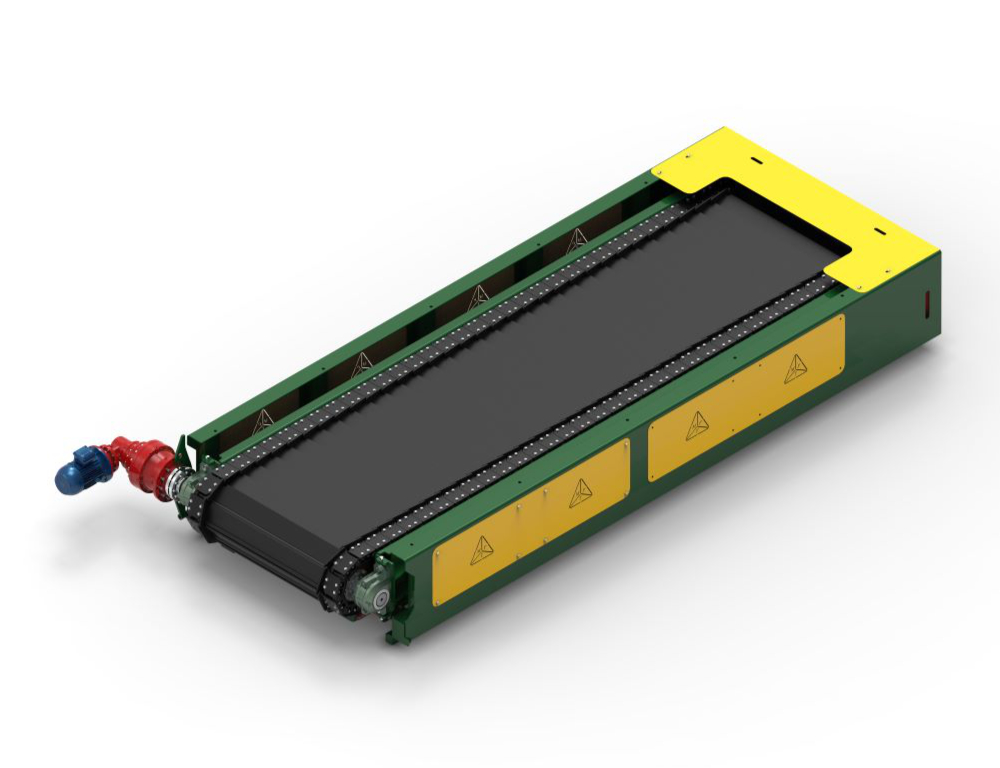

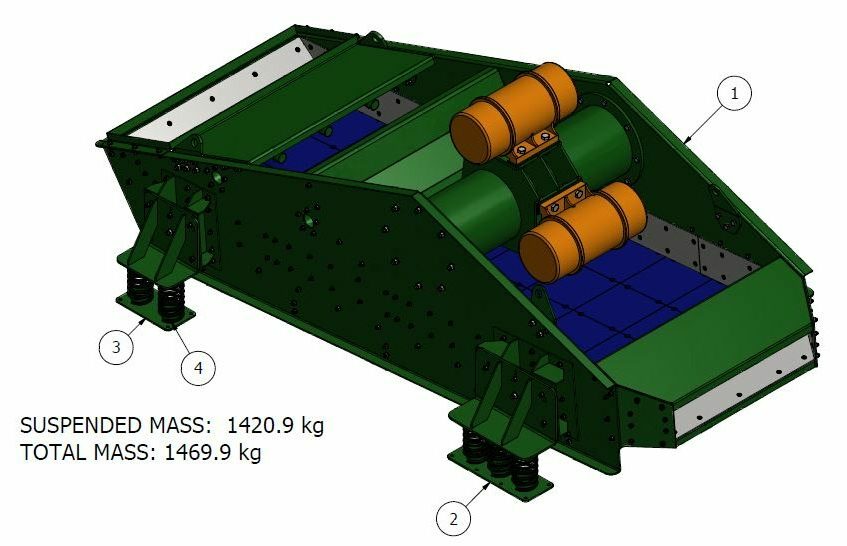

The TITAN VIBRATING SCREEN is a MechProTech OEM, namely our internal screen brand. We proudly manufacture this locally at our in-house workshop in Benoni, South Africa. With applications in harsh mining environments, the product is designed to endure extreme conditions of the industry.

Being tailored to meet the needs and requirements of each of our clients, each screen is designed and created in accordance with the application requirements. The product’s capability of high screening performance has suited process plants well across the board.

The standard TITAN screen runs at 5G’s linear vibration force, built with sound structural integrity and is checked by advanced Finite Element Analyses (FEA).

All deck beams and drive beams are stress relieved and machined, with all the material contact surfaces being lined with VRN400 liners or rubber etc. Adjustable foot mounts are included in cases where the adjustability of the deck is necessary. The TITAN screen is used in a variety of applications such as scalping, protection, sizing classification, washing, de-sliming and de-watering.

The TITAN VIBRATING SCREEN product range includes:

Single deck screens

Double deck screens

Triple deck screens

De-sliming screens

De-watering screen

High-frequency screens

Products

Get in Touch With Us Today!

We understand the unique challenges of this industry and are dedicated to helping you overcome them. Contact us today to learn how we can help you enhance your mining operations and achieve your business objectives.

Titan Vibrating Screen design features include:

- Vibratory Drive Motors, Oscillating mounts and isolation coil spring suspension.

- Machining of cross beams and drive-beam.

- Priming of all surfaces using epoxy primer.

- An abrasion-resistant impact bed.

- A wear-resistant side walls and discharge lip.

Static Screens

The MPT Static SCREEN is a MechProTech OEM product, manufactured in-house at our workshop in Benoni, South Africa

The static screen is constructed with S355 sides and VRN Grizzly bars . The spacing of these bares are adjustable to suit Process/circuit requirements

Contact us

Leading designers and suppliers of mineral process equipment and solutions.

Send us a message

"*" indicates required fields