Modular Pilot Plants

Modular Pilot Plants

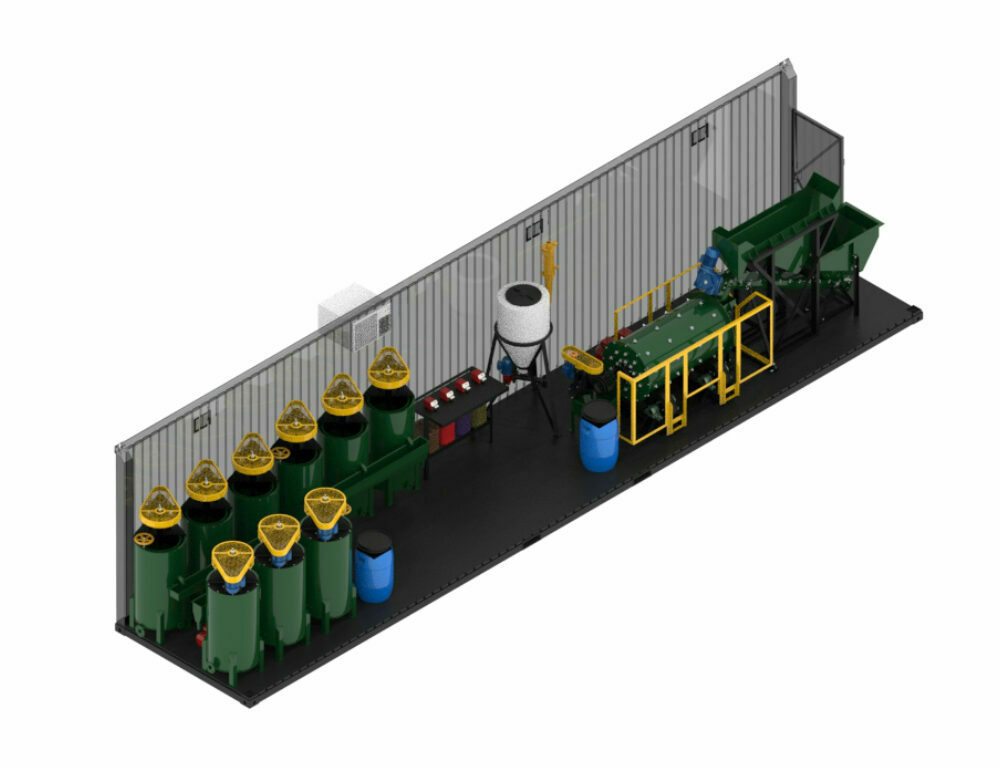

MechProTech, with its extensive range of OEM equipment and bespoke designs supplied to the industry, has supplied several Pilot and Modular package plants. The design and business philosophy of MPT is that the equipment must be designed to be built, assembled, and tested in the workshop prior to despatch to the site. This reduces risk and unnecessary site work where cost is the main risk.

MechProTech has supplied the following Pilot Plants because of this philosophy:

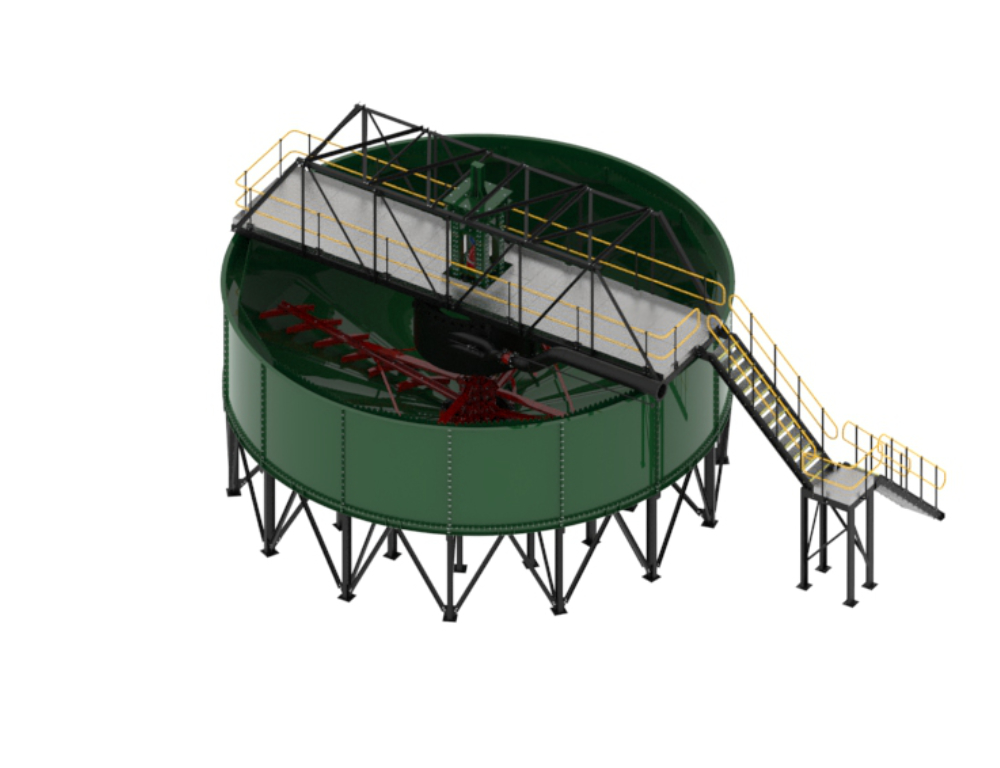

- Pilot Biox Thickeners plant, South Africa 3-ton Gold and Gravity Recovery Plant, Tanzania

- 50-ton Gold Alluvial wash plant, gravity recovery circuit with final recovery & smelting, Mozambique

- 80-ton tph Gold Alluvial wash plant, gravity recovery circuit with final recovery & smelting, Angola

- 400 kg tph mill and float Containerised test pilot plant Zimbabwe

- 1tphr Crush Mill and Gravity recovery containerised plant DRC

- 30 tphr Hard Rock Crushing screening Milling and Gravity Gold recovery plant Guinea

- 100 tphr Alluvial Gold Washing and Gravity Recovery and final recovery plant Guinea

- 200kg Milling Test Rig plant for Anglo American Research lab

- 5-ton tphr Trommel Feed circuit for screening Test material Anglo American

- 5-ton tphr scrubber feed and screening test Pilot plant for Tanzania

- 5-ton tphr Sulphur Mill and Classification Plant Madagascar Mill fitted with SS Drum

- 60 tphr Scrubbing screening classification Plant Manganese Gabon

- Three tphr Chrome Spiral Classification plant South Africa and Zimbabwe

- 1-ton atmospheric gold eluting plant for South Africa

Paint Batching Plant for Zinc-Based Resin Plant with Mixer and Stainless Tanks.

Other larger plants we have collaborated on are:

- 250-ton tphr wash plant for gold with a 120 tphr Milling capacity for gravity recovery, Angola

- 15-ton tphr hard rock mill and Gravity recovery Plant DRC

- 150 tphr Manganese Scrubbing washing and classification plant Gabon

MechProTech also collaborates with Partners in Industry to Supply Modular packaged equipment which is more details in the descriptions below:

- Modular comminution Circuit.

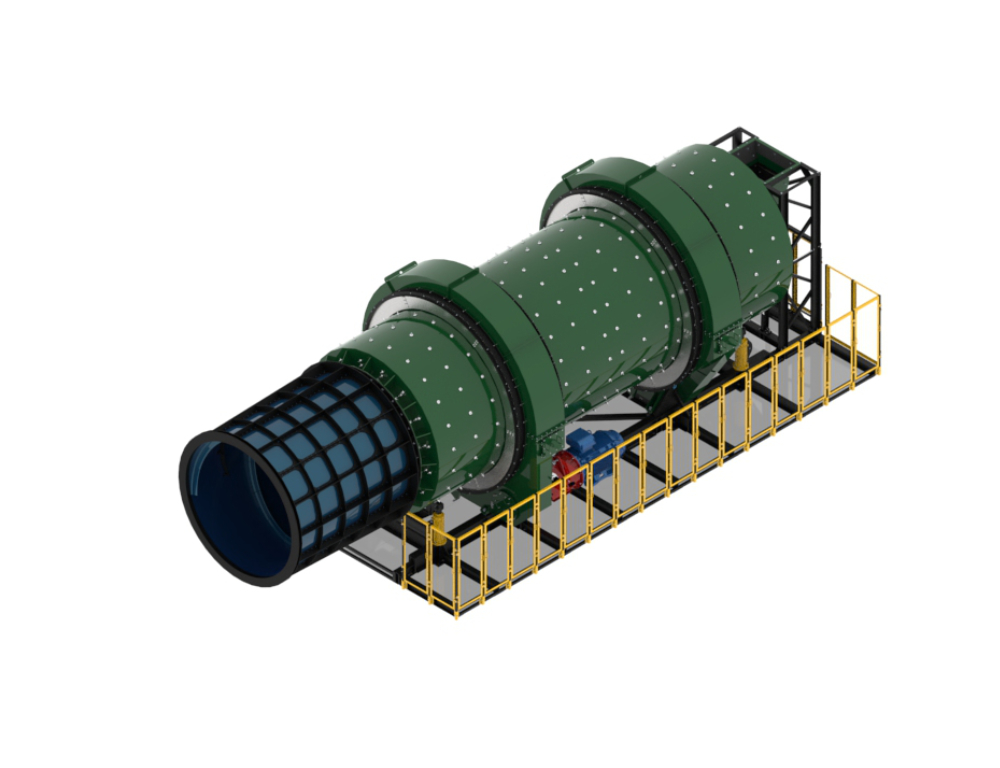

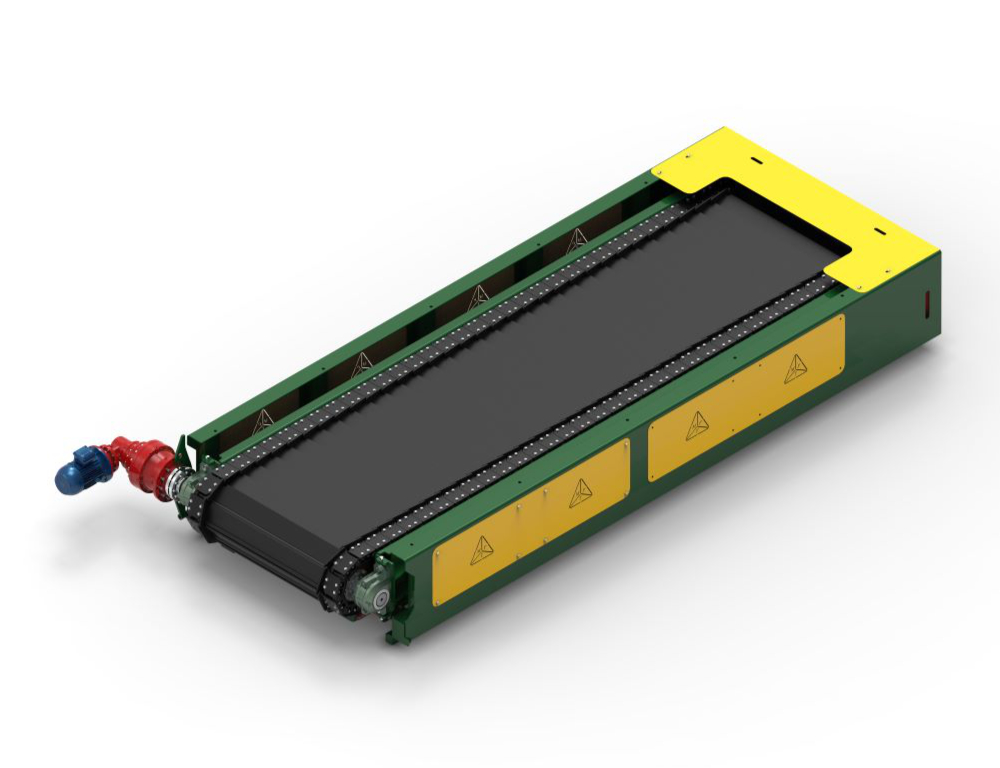

MPT have supplied with our Titan Mill a package consisting of, but not limited to, the following

Modular Comminution Circuits

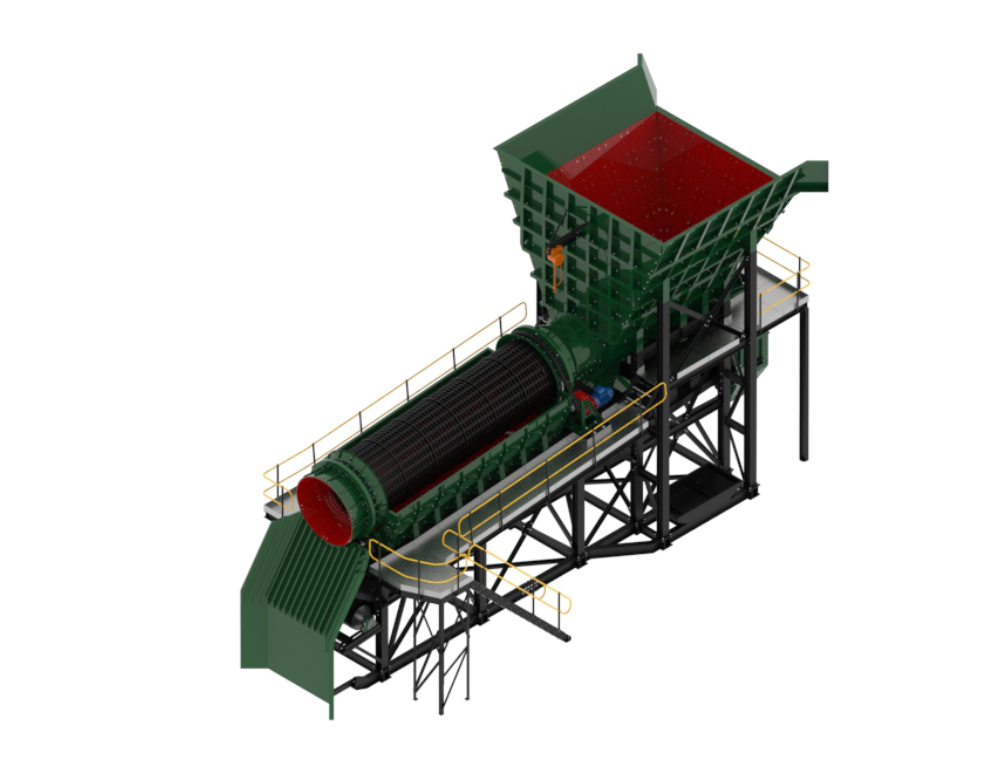

Modular Scrubbing Circuits

These typically include:

- MPT titan scrubber

- Feed bin

- Push feeder (can be substituted with an apron or grizzly feeder)

- Scrubber feed conveyor

- Support structure & access stairs

- Discharge sump

- Oversize chute

- Underflow pumps

- Piping & valves

- Electrical mcc (containerised or free standing)

- Hydraulic systems for the scrubber and push feeder

Contact us

Leading designers and suppliers of mineral process equipment and solutions.

Send us a message

"*" indicates required fields