Hi-Rate Thickeners

Hi-Rate Thickeners

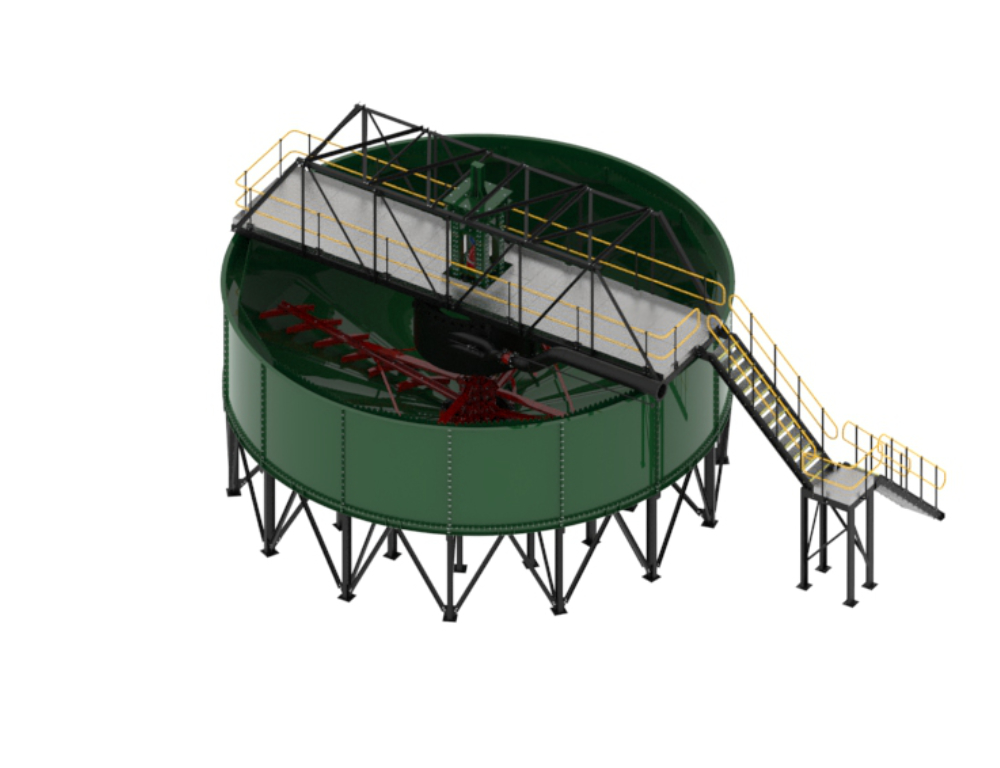

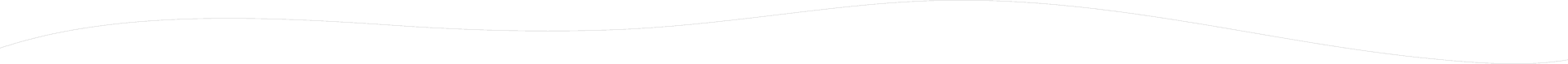

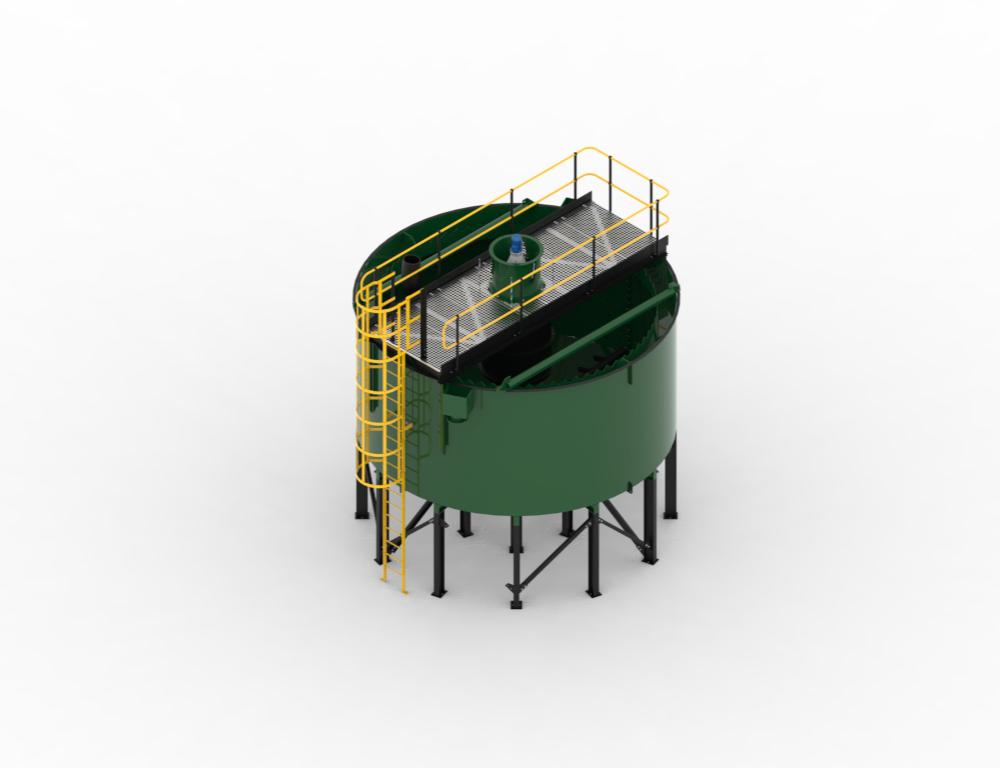

The HI-RATE THICKENER is a MechProTech OEM product manufactured in-house. It has a structurally grated walkway across the top. Suspended from the walkway at the top of the tank is the drive assembly consisting of a gearbox driven by an electric motor and the hydraulic lifting system.

Design & Dimensions

Segmented design for on-site bolt-together function, whilst welded options are also available. Tank Segments are bolted together and partitioned to be transported by normal truck gauge. Dimensions would call for a maximum width of 3.9m and a maximum height of 4.7m.

Hi-Rate Thickener design elements include the following:

- Mechanical lift mechanism drive head complete with planetary gearbox drive.

- Two full-radius rake arms and two half-radius rake arms, complete with a cone scraper & MechProTech high-efficiency constant velocity rakes.

- Drive control panel with Variable Speed Drive (VSD), a warning light and a siren for torque warning.

- Mild steel painted bridge with hot dip galvanized walkway.

- Hand railing for support of the drive, feed well and feed pipe.

- MechProTech Flow-efficacy feed well, internally lined with rubber along with a rubber-lined tangential feed.

- Tank floor and side walls are constructed from 6mm mild steel plates, painted to MechProTech specification with a two-coat epoxy system.

- Mild steel painted braced support columns.

- Stairway or Cat ladder access options are also available.

- Trail assembly is executed on our workshop floor.

Function

The HI-RATE THICKENER feed well height is adjustable to allow for control of the secondary dilution and levelling thereof so that there is even water flow over the total circumference of the feed well. Slurry enters the notched proprietary feed well via a tangential inlet pipe. Flocculent is also added; thus, mixing between flocculent and slurry is completed in the proprietary feed well. To aid settling and thickener performance, MPT can install high circulating pumps to increase supernatant back into the feed stream to improve the thickener’s floc generation and settling performance.

The rake design allows solids to settle to the conical floor of the tank, where the rakes move the material towards the central outlet. The scraper on the bottom of the rake shaft ensures that the outlet pipe remains unblocked. The drive assembly is either mechanically lifted on torque cams or fitted with a hydraulic lift system that progressively lifts the rakes as process torque increases. When there is an increased level of solids, the rake shaft will automatically raise to the correct level because of the torque monitoring hydraulic system or the mechanical torque cam.

MechProTech Thickener design is a bolt-together design suitable for standard road transport or containerisation. Thus, the units are fully fitted in our workshop and, when delivered, are ready for installation with reduced erection times.

Contact us

Leading designers and suppliers of mineral process equipment and solutions.

Send us a message

"*" indicates required fields