Reagent Plants

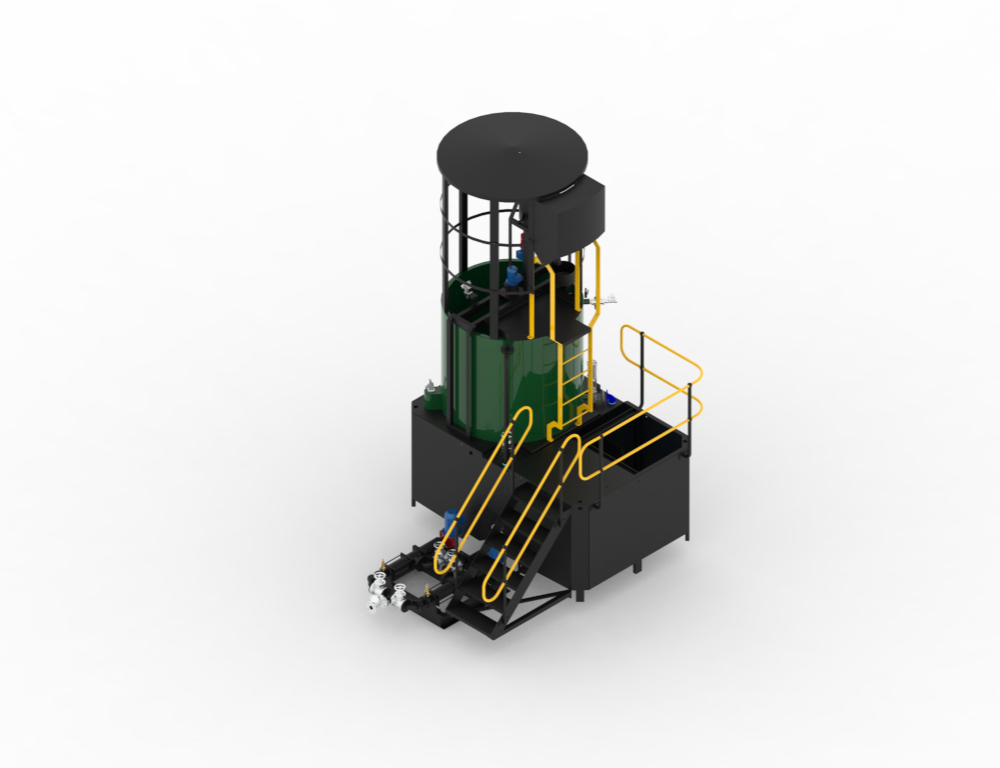

Hydramix Reagent Plant

The HYDRAMIX REAGENT PLANT is a MechProTech OEM product and is manufactured in-house at our workshop in Benoni, South Africa. The design minimises the tank volume and footprint required to support the hydration time for the Floc /Reagents. The cyclic tank design means that transfer pumps are not necessary and that the tanks cycle from make-up to hydration to dosing.

Types of HYDRAMIX REAGENT PLANT

- Tank Farm Reagent and Floc Plant

- Compact Reagent and Floc Plant

Get in Touch With Us Today!

We understand the unique challenges of this industry and are dedicated to helping you overcome them. Contact us today to learn how we can help you enhance your mining operations and achieve your business objectives.

Reagent Plants

HYDRAMIX Tank Farm

The Hydramix Tank Farm offers Mixing & Hydrating of powered & liquid reagents up to 500 kg/ hr.

The Hydramix Tank Farm consist of two, three or more tank designs that minimise the volume required and ensure correct hydration times are achieved at max flow. Hydramix Hi-rate floc plants have the following features:

- Fully integrated plant, including loading system for reagent, access stairway and platform

- Post-dilution of hydrated dosed solution

- Water-based reagent transport minimises capital cost because no blowers and rotary valves are required and ensure wetting of powered and no “fisheyes”.

- Open mixing system easy to clean and inspect for blockages

- High power mixing of reagent with liquid-sloped polished stainless tank sides ensures ease of cleaning

- Single or multi-dosing pump options

Reagent Plants

Compact Series

The Hydramix compact plant offers a cost-effective Mixing of powder & liquid reagents up to a max of 9kg/hr at 0.1% make-up solution & 1 hr hydration time.

Modular Designed mixing and hydrating system and have the following features:

- Stand Alone self-contained, including control system.

- Built-in lifting points for easy relocation. Covered structure option for hostile environments.

- Overflow containment and diversion to a single point from all tanks simplify overflow management.

- A baffled hydrating tank prevents short circulating.

- Fully or semi-auto options to suit client requirements

- Single or multi-dosing pump options

Reagent Plants

Make Up Plant

The Reagent Makeup Plant is an essential facility in mining operations,.

Mechprotech has developed customizable facility that caters to the specific needs of any mining operation .

The MPT reagent make-up plant provides control over reagent quantities and compositions.

Contact us

At MechProTech, we understand that each client’s needs differ in the industry.

Contact us today to discuss your specific requirements.

Send us a message

"*" indicates required fields