Mixers & Agitators

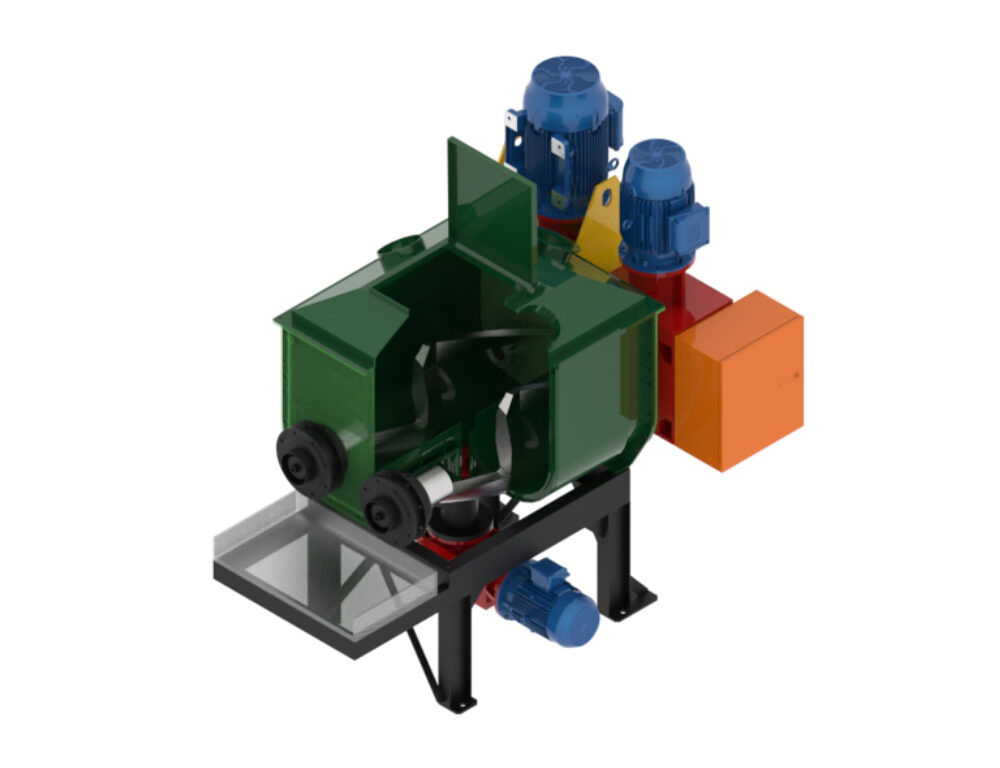

Z-blade mixer

The Z-blade of the mixer can be manually operated or automated, depending on the needs and requirements of the client. When automated, the unit is programmed by PLC; thus, the blend cycling is started via a start control button on the HMI.

The blending runs in accordance with the predefined run sequence with respective blending speed, duration, and direction changes. After the predetermined run time lapses, the blender will stop automatically.

The Z-Blade mixer design options include:

- A stainless-steel chamber and blades for food-grade operations.

- A mild steel construction with rubber lining and painted finish.

- A heating jacket is included with the chamber if required.

- PLC-programmed or manually operated.

MechProTech Mixer Product List:

- A mixing chamber.

- Direct drive-through gearboxes.

- A mechanical seal arrangement for the mixing chamber sealing.

- An electrical control panel for the unit is an optional extra.

- A test run and commissioning of the unit can be conducted at our workshop.

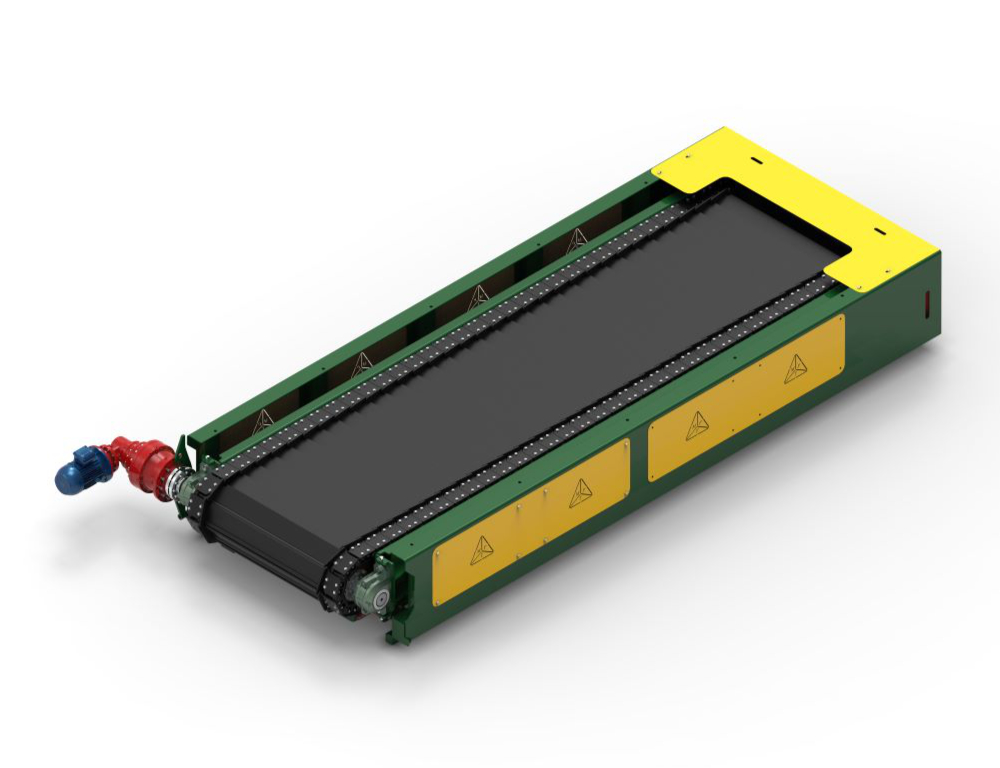

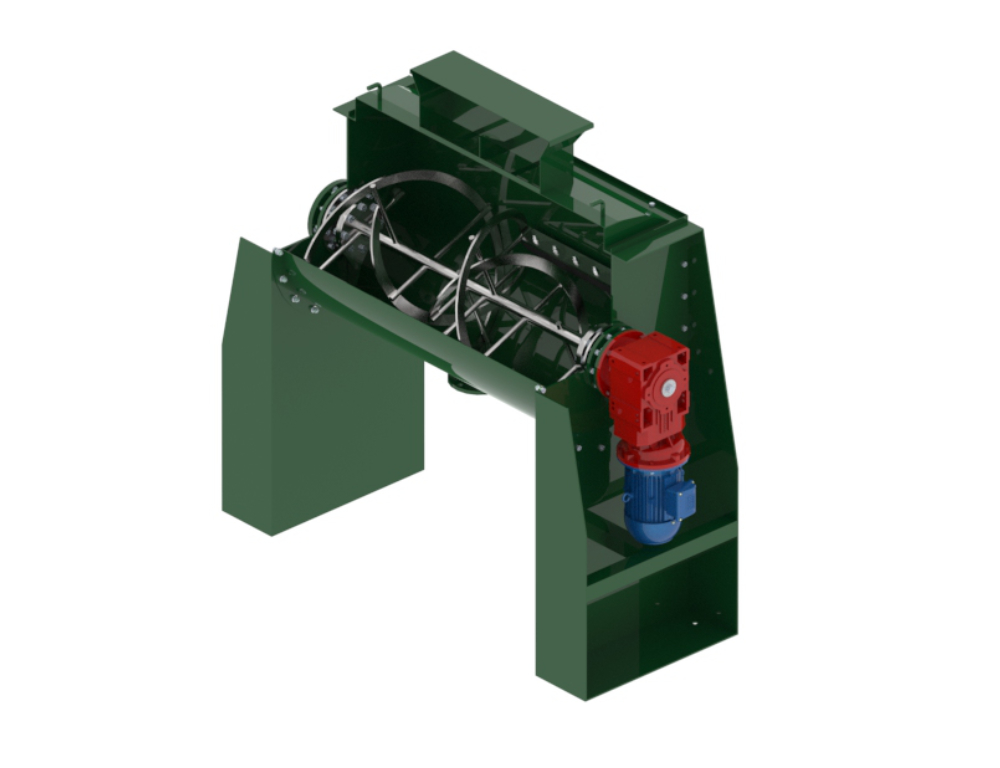

Ribbon Mixers

These mixers are designed to efficiently blend dry or wet materials, ensuring uniform mixingand achieving desired product consistency. With the Mechprotech unique ribbon-shaped agitator blades, this mixer provide excellent batch homogeneity, making them ideal for applications such as food processing, pharmaceuticals, chemicals, plastics, and more.

Mechprotech provide design alternatives for the ribbon blade mixer that are adapted to your unique needs, such as a stainless steel chamber and blades for food-grade operations, mild steel rubber-lined or painted solutions, and the incorporation of a heating jacket if necessary.

Get in Touch With Us Today!

We understand the unique challenges of this industry and are dedicated to helping you overcome them. Contact us today to learn how we can help you enhance your mining operations and achieve your business objectives.

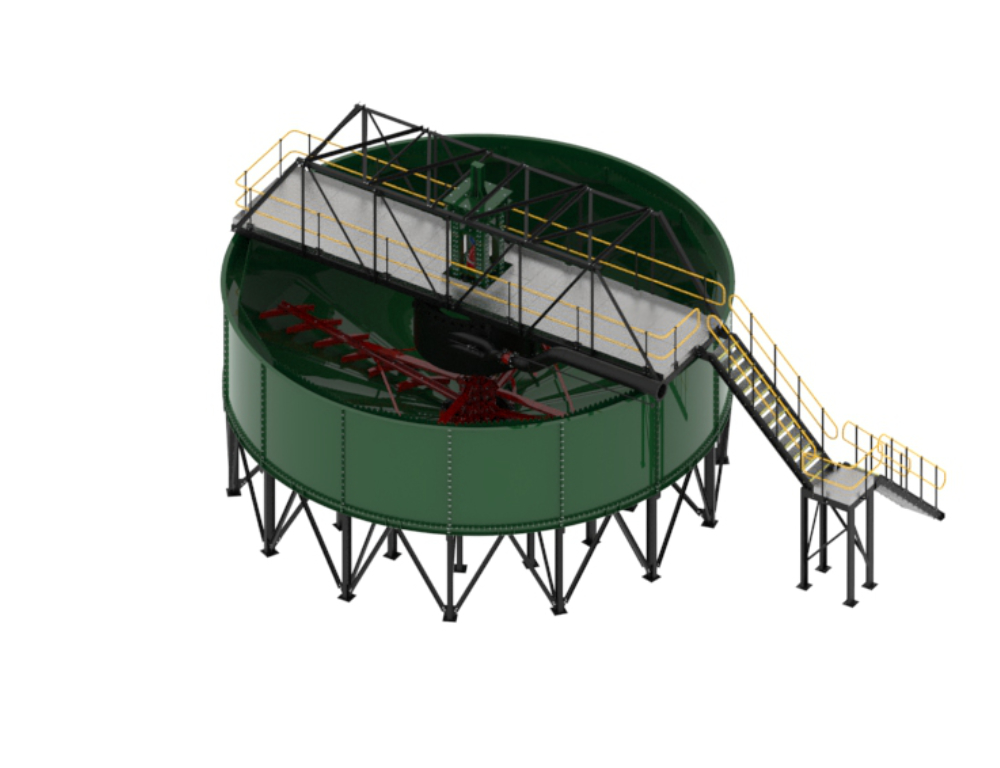

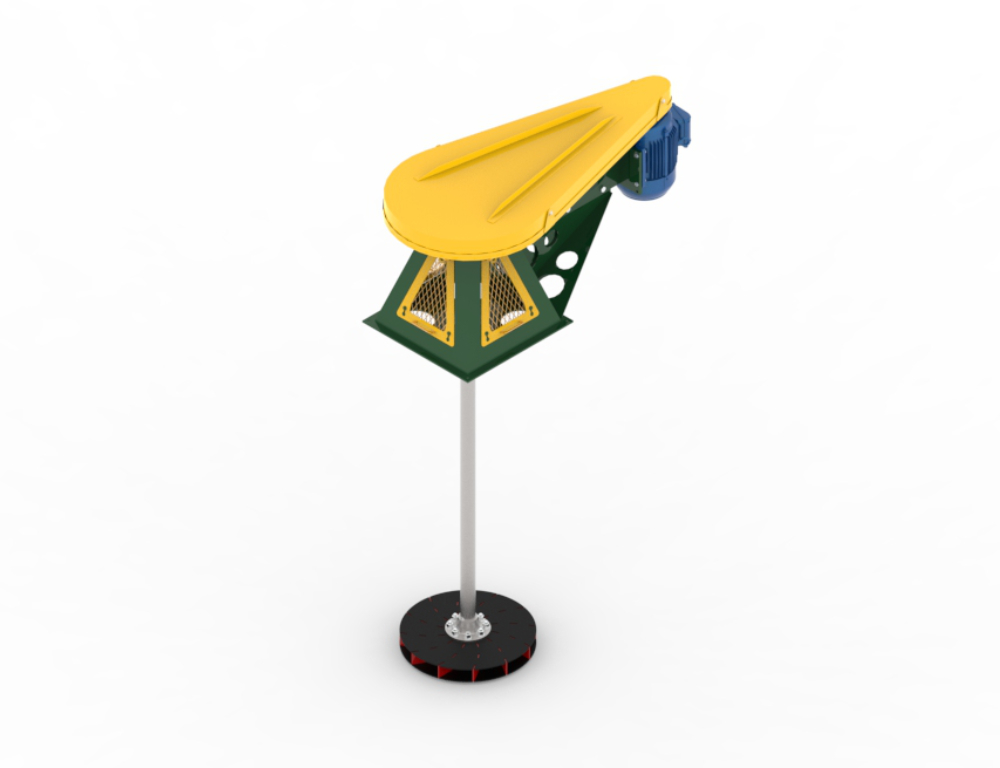

Agitators

Conventional Mechanical Mixer for Mining and Industry processes of Mining Water Treatment, Paper and Pulp, Oil, Food, and Chemical industries, including Paint. MechProTech will design and offer Mixer drive units ranging from 180 watts to 400 kW’ to suit the application.

Titan Mixers Design comprises the following arrangements:

- A mounting arrangement can be designed to suit bridge applications baseplate, pedestal, or clamping arrangement for heavy to light applications.

- Dust cap, lip seal packed gland single and double mechanical seal to cater for various atmospheric and high-pressure applications.

- Construction material varies from Carbon steel, stainless steel, Titanium Hastelloy and other specialised steel and metals. All of these can be used to manufacture solid or hollow shafts, impellers and couplings.

- Depending on specification and equipment working conditions, the coating can be applied to the material. The coating range from: – Priming of all surfaces using Zincodic Zinc-based epoxy primer and topcoat ( ISO 2944 C5 VH) and (ISO 12944 IM# 4000hrs) Proprietary colours and Paint spec. – Natural rubber polyurethane, Butyls, PTFE, Halar, and Ultralar wear-resistant coating.

Impellor ranges included:

MechProTech’s process and mechanical simulation programs have yielded supplier impellor designs and configurations that are proprietary to the Titan Brand and which yield benefits to the Client and mixing applications.

Liquid- Liquid mixing

Liquid Solids Mixing

Solid Solids Mixing

Paste mixing

Liquid Solids Suspension

Swirl Flow Mixing

Hi-Attrition Mixing

Contact us

At MechProTech, we understand that each client’s needs differ in the industry.

Contact us today to discuss your specific requirements.

Send us a message

"*" indicates required fields