Choosing a suitable material handling feeder is crucial for optimising operations and improving efficiency in mineral processing and handling industries.

With numerous options available, making an informed decision tailored to your specific requirements can significantly impact your operation’s productivity and cost-effectiveness.

MechProTech, a leader in the mineral processing sector, offers a range of solutions designed to meet diverse material handling needs. This article delves into considerations and available feeder options, guiding you toward the optimal choice for your operation.

Understanding Your Material Handling Needs

The first step in choosing a suitable feeder involves comprehensively understanding your material handling requirements.

Different materials, from the heavy ores to the fine powders, present unique challenges in processing and transportation. The material’s abrasiveness, size, moisture content, and corrosiveness can significantly influence your feeder choice. Additionally, evaluating your operation’s capacity needs, spatial constraints, and integration with existing systems is crucial.

The correct feeder accommodates the material properties suitable to your business’s operation. They can be chosen to fit seamlessly into your workflow, allowing you to achieve the most operational efficiency and reduce costs.

Types of Feeders and Their Applications

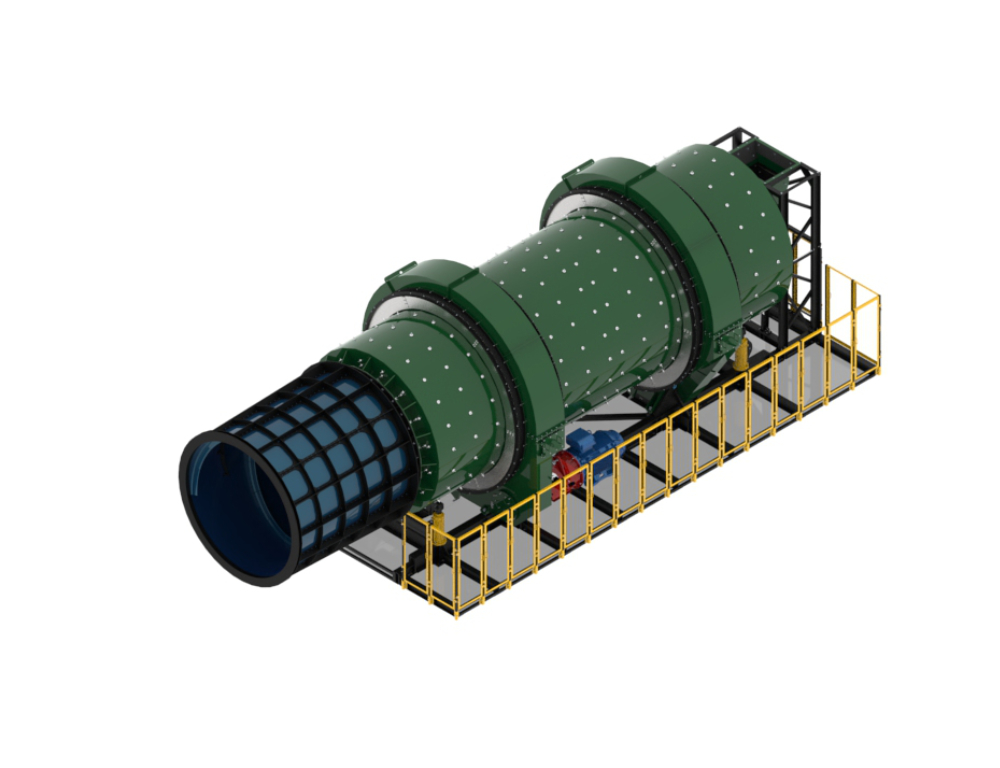

Apron Feeders

Apron Feeders are designed to handle heavy, abrasive materials such as minerals and ores.

These feeders are renowned for their durability and capacity to manage large volumes, making them ideal for demanding mineral processing applications. Apron feeders consist of overlapping heavy-duty pans or aprons mounted on chains conveying material at a controlled rate during the feed. Their resilience against wear and tear makes them a long-term, cost-effective solution for heavy-duty operations.

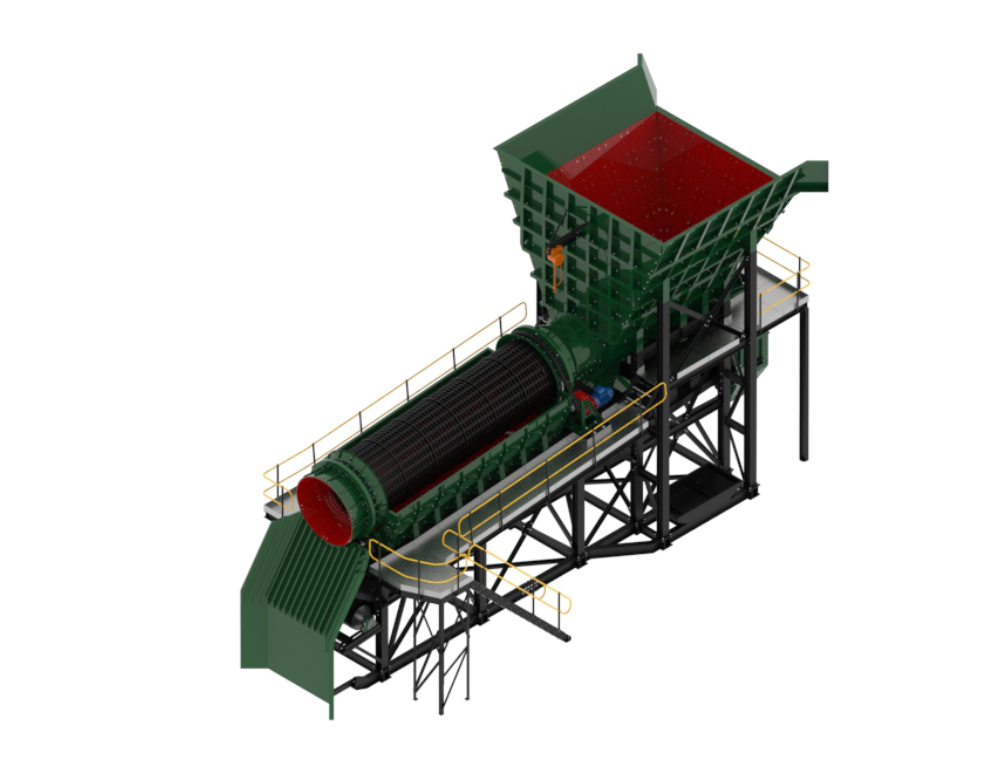

Push Feeders

Push Feeders, known for their simplicity, are suitable for handling fine, powdery materials.

They push material from a storage bin or hopper to be handled by the processing system. Their straightforward design and operation make push feeders one of the more cost-effective options for materials requiring gentle handling to prevent degradation or compaction.

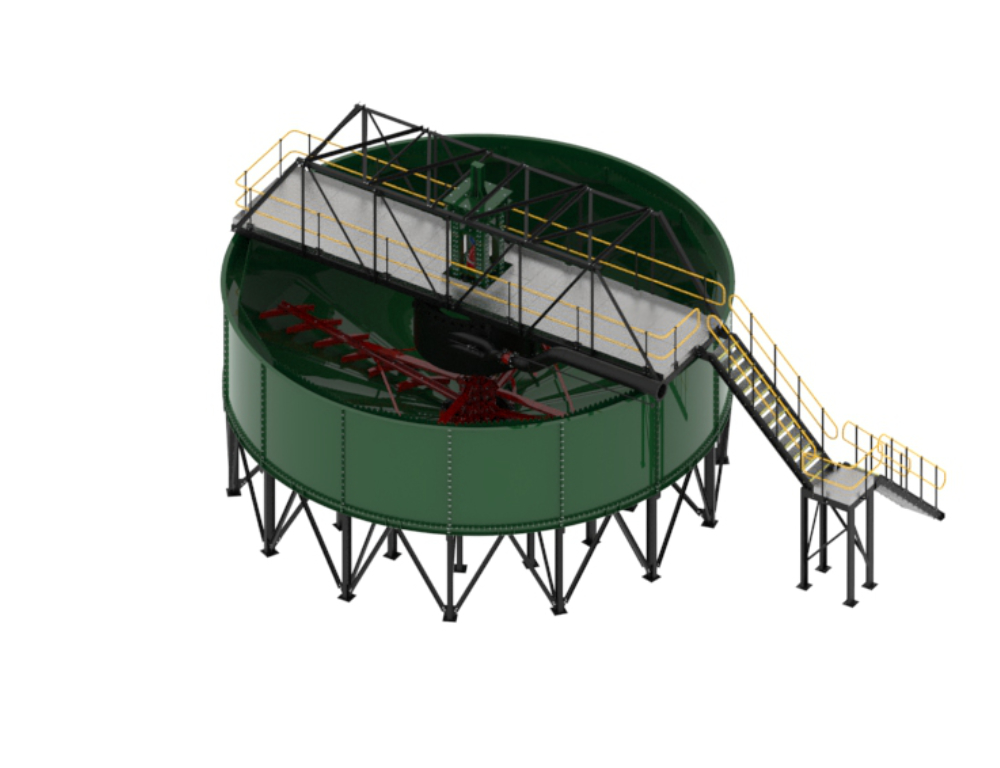

Pan Feeders

Pan Feeders offer versatility across light – and heavy-duty applications.

They can handle many material types, including high temperatures or challenging properties. The pan feeders are particularly useful for operations requiring a feeder that can adapt to varying material conditions without compromising efficiency or throughput.

Considerations in Choosing the Right Feeder

When selecting a type of feeder, several critical factors can be considered:

Characteristics of Material:

When selecting the right feeder for handling materials, it’s important to consider the various properties of the material being handled.

Abrasiveness and moisture content are two important properties when selecting a feeder material. If the material used in the process is too wet or dry, it can affect the feeder’s ability to handle and dispense it.

Therefore, choosing a feeder compatible with the specific material properties is essential to ensure optimal handling efficiency and prevent premature wear and tear on the feeder components is essential.

Throughput and Capacity:

It is imperative to carefully consider and determine the appropriate capacity of the feeder to match the specific requirements of your operation.

This involves taking into account various factors such as the type and quantity of material being fed, the desired rate of feed, and the overall production goals. By selecting a feeder with the appropriate capacity, you can ensure that the feed process operates smoothly and efficiently, resulting in optimal productivity.

On the other hand, choosing a feeder with a too low or too high capacity can lead to various issues, such as uneven feeding, material jams, and excessive wear and tear on the equipment. These can negatively impact productivity and increase maintenance costs.

Integration and Space:

When selecting a feeder, it is essential to consider its integration with existing systems and the available space.

The feeder must be compatible with the current setup and should not require significant modifications or additional equipment to function correctly. Additionally, the feeder’s dimensions and design must be carefully evaluated to ensure it fits within the available space without causing any obstructions or safety hazards. Attention to these details can help ensure the chosen feeder operates efficiently and effectively within the intended environment.

Maintenance and Durability:

When selecting feeders for your operations, it’s wise to look for models that are easy to maintain and offer a long lifespan.

These feeders should be designed for minimal wear and tear, and regular maintenance should be simple. This helps to reduce downtime, which can be costly and disruptive to your operations. Additionally, feeders with a long lifespan offer a better return on investment, as you won’t need to replace them as frequently. Considering these factors, you can ensure that your feeders are reliable, cost-effective, and easy to manage.

Cost Implications:

When considering investment options, it’s essential to evaluate the balance between the initial upfront investment and the potential long-term operational savings.

For example, a more expensive feeder may offer lower maintenance costs and better durability, translating to significant savings over time. By considering factors such as maintenance costs, replacement costs, and expected lifespan, you can make a more informed decision about which investment option will ultimately provide the best value for your money.

Our Range of Material material-handling equipment

MechProTech’s OEM feeder range consists of the following:

- Apron Feeders – Titan AFM

- Push Feeders – MPT Push Feeder

- Pan Feeders – MPT Pan Feeder

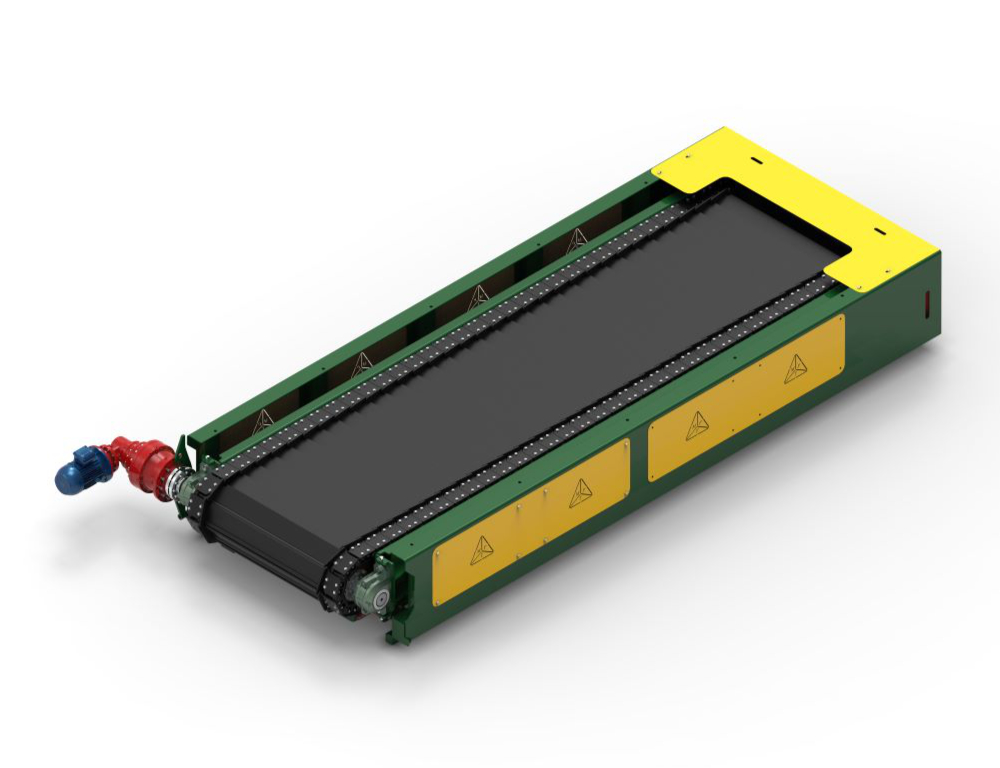

- Conveyor Systems

- Additional Feeders

Trust MechProTech’s Material Handling OEM Solutions

Choosing a suitable material handling feeder is a critical decision that can significantly affect your operation’s efficiency, cost, and productivity.

By understanding your material handling needs, evaluating the different types of feeders, and considering key factors such as material characteristics and operational requirements, you can make an informed decision that best suits your operation.

MechProTech, with its expertise in mineral processing solutions, stands ready to assist you in selecting and implementing the ideal feeder for your needs, ensuring that your operation runs smoothly and efficiently.