Comminution is a mechanical process that involves breaking down large solid materials into smaller particles.

This article delves into the various comminution methods and focuses on the solutions provided by MechProTech as an Original Equipment Manufacturer (OEM).

Comminution in Industries

Comminution is crucial in many industries, including mining, mineral processing, and manufacturing.

Mining

Comminution is used to extract valuable minerals from ores. The process involves crushing and grinding the ore into smaller particles, which can then be separated from the waste materials.

Mineral Processing

Comminution is used to separate valuable minerals from waste materials. The process involves crushing and grinding the ore into smaller particles, which can then be separated using various techniques such as flotation, gravity separation, and magnetic separation.

Manufacturing

Comminution produces powders and fine particles in various products, such as pharmaceuticals, cosmetics, and food additives. The process involves grinding and milling the raw materials into smaller particles, which can be used to create the final product.

The efficiency of comminution can significantly impact the cost and quality of the final product. It is essential to optimise the comminution process to ensure it is as efficient as possible. This can be achieved through the use of advanced technologies and equipment and the development of new and innovative comminution techniques.

Comminution in Mineral Processing

Crushing Techniques in Comminution

The first step in comminution is crushing, which involves applying force to materials to break them into smaller, more manageable sizes.

Crushing is a crucial step in the comminution process, setting the stage for further processing. The smaller particle sizes produced by crushing make separating and extracting valuable materials from the more extensive materials easier. Additionally, smaller particle sizes can improve the efficiency of downstream processes, such as grinding and milling.

MechProTech’s Rolls Crushers, including the Smooth Rolls Crushers, are designed for reliability and high performance. They feature twin manganese steel lined rollers, adjustable gap settings, and independent roll drives, ensuring efficient and even wear.

Product: MechProTech Rolls Crushers

Grinding Methods in Comminution

Grinding is the secondary stage of comminution, which involves reducing the size of particles to a finer level.

This process is essential for producing fine particles in various industries, such as pharmaceuticals, cosmetics, and food processing. Grinding is achieved using different types of equipment, such as ball mills, rod mills, and vertical mills, depending on the material being processed and the desired particle size. The efficiency of the grinding process is critical in achieving the desired particle size distribution and minimising energy consumption.

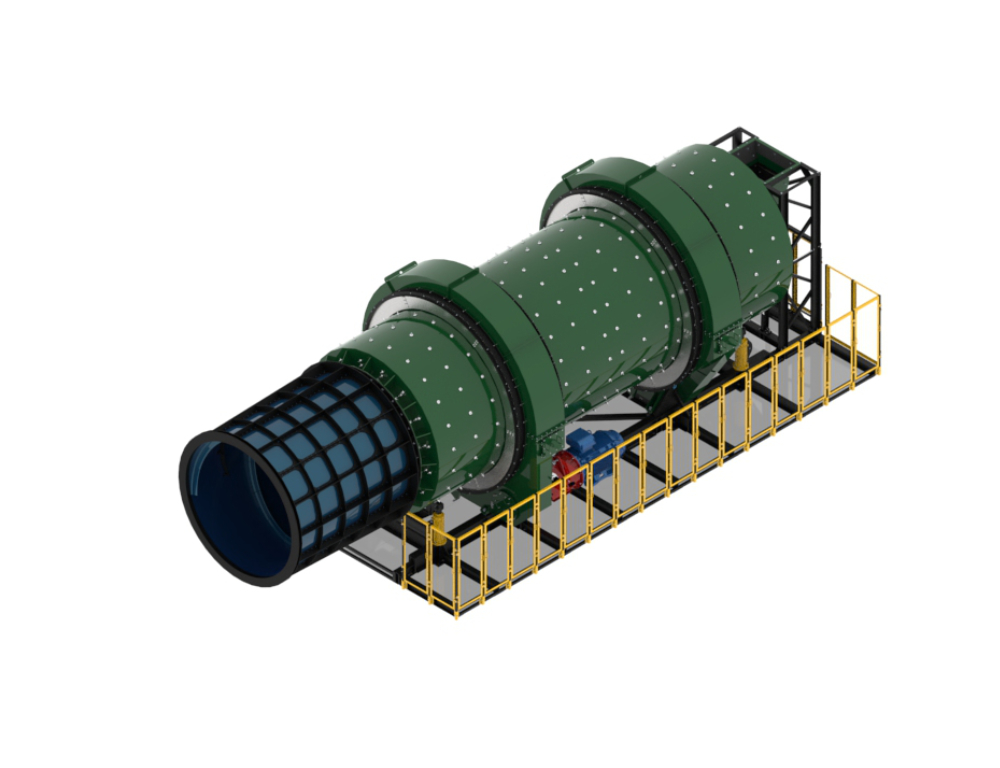

MechProTech offers a range of grinding mills, including the Titan Mill™ Gear-Driven and Olympian Roller-Driven ranges. These mills cater to various applications with features like double pinion and girth gear drives, ensuring longevity and efficiency.

Product: MechProTech Grinding Mills

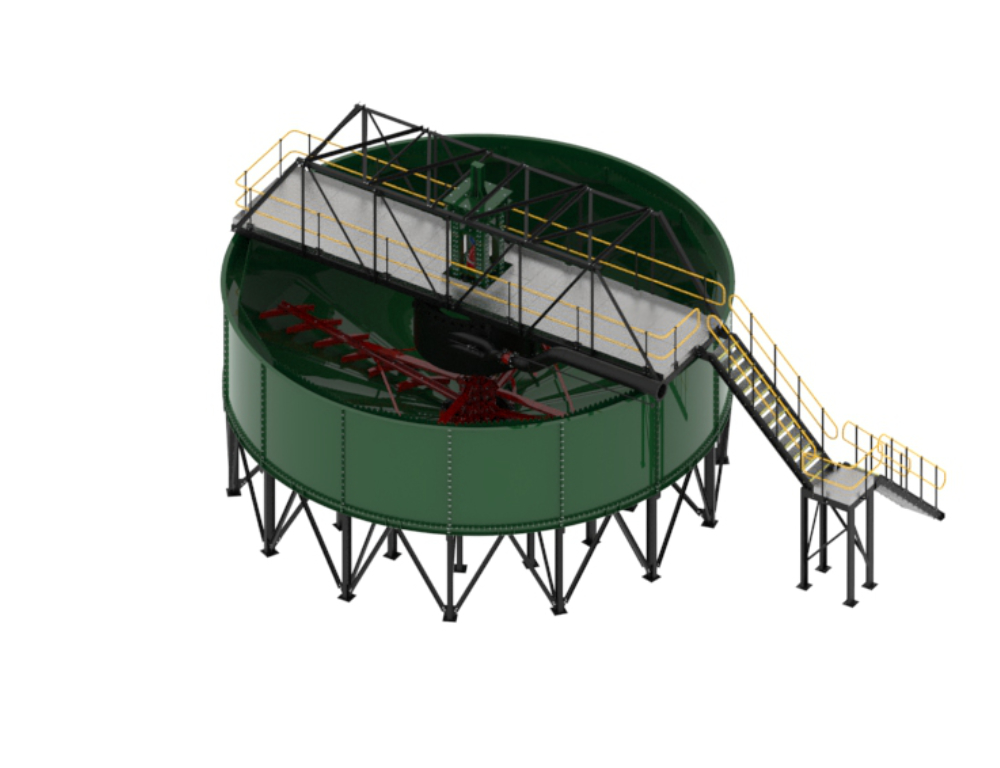

Scrubbing in Comminution

Scrubbing is a process that involves the removal of impurities from the material being processed.

In the context of comminution, scrubbing is essential as it helps improve the process’s efficiency. The material becomes more homogeneous by removing impurities, making it easier to grind or crush. This results in a more efficient comminution process, significant cost savings, and improved product quality.

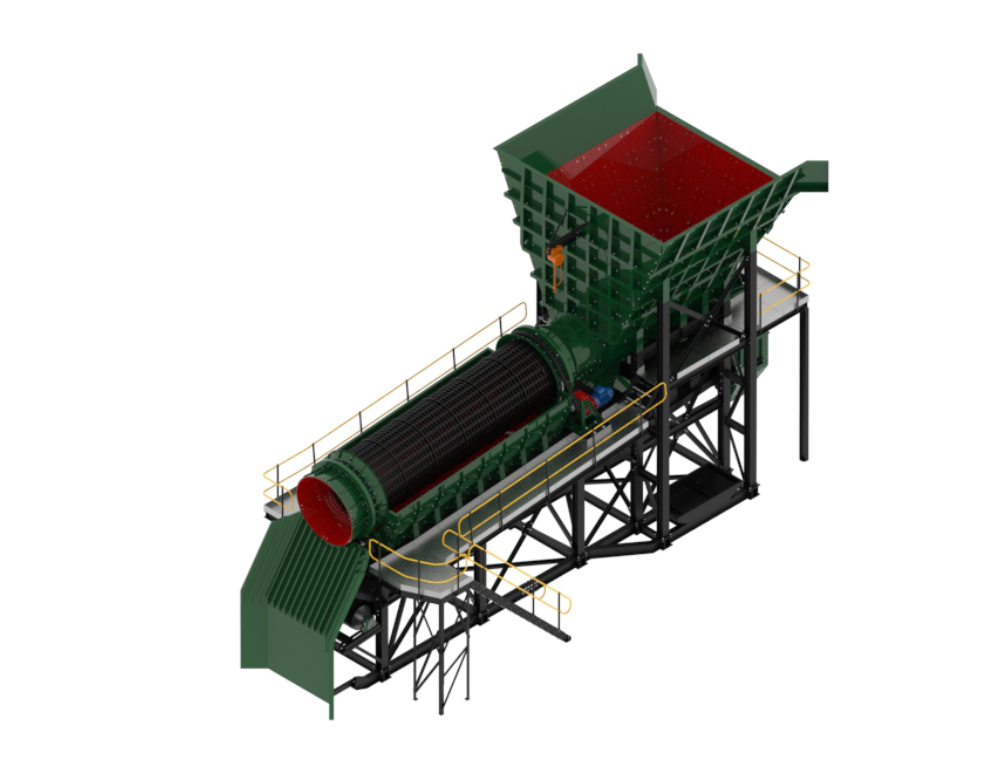

MechProTech’s scrubbers, such as the Autogenous Scrubbers and the Titan GDS, offer modular designs and efficient scrubbing capabilities, which are essential in processing operations.

Product: MechProTech Scrubbers

Innovations and Technological Advancements

Let’s take a further look at MechProTech as an OEM of mineral processing equipment:

Scrubbers

Usage: MechProTech’s scrubbers are primarily used for the intensive washing of bulk materials. This process is essential in removing impurities and preparing the materials for further processing.

Features and Design: The Titan GDS scrubber, for instance, is fixed on a rigid, heavy-duty steel base frame with safety guards around rotating equipment. It supports the shell with hydrostatic bearings and includes an oil lubrication station for efficient operation. The design also features a supported roller carriage, minimising wear and tear. Moreover, these scrubbers are designed for quick manufacturing and easy site assembly, offering cost savings in capital expenditure.

Product Variants: The range includes Autogenous Scrubbers, Titan GDS Design, and Complete Skid Mounted Circuits, each with unique features such as high-efficiency scrubbing and modular designs.

Applications: These scrubbers are vital for ore preparation and impurity removal in mining and mineral processing industries.

Grinding Mills

Usage: Grinding mills are used for material grinding, which is a critical step in reducing the size of ores and minerals for further processing.

Features and Design: The Titan Mill™ Gear-Driven Range, for example, features a lubricated girth gear-to-pinion system with premium efficiency electric motors. This design maximises the life of liners and gears and allows operation in either direction. The mills are modular in design, requiring no exceptional civil work, thus offering cost benefits. The product range includes Overflow Ball Mills, Grated Ball Mills, Peripheral Discharge Ball Mills, and Rod Mills.

Applications: These mills are integral in mineral processing for ore grinding and preparing the material for beneficiation steps.

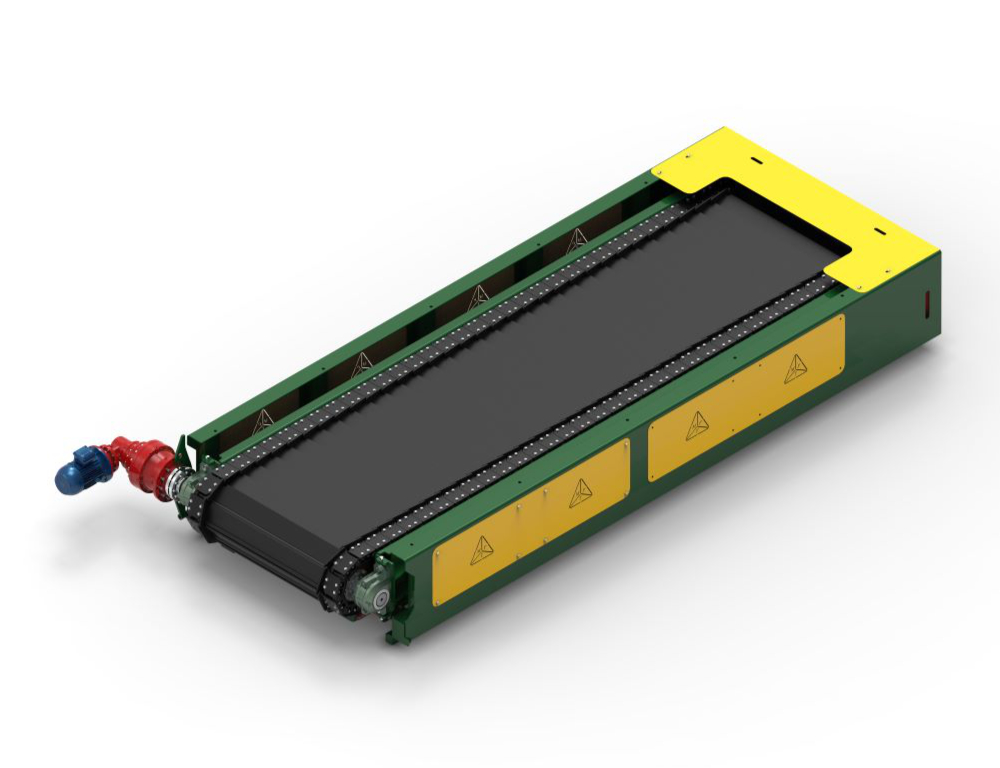

Rolls Crushers

Usage: Designed for reliable and high-performance crushing operations, Rolls Crushers are essential in the initial stage of comminution.

Features and Design: The Smooth Rolls Crushers have twin 950mm diameter manganese steel lined rollers. They feature wear plate feed chutes, heavy-duty bearings with gap adjustments, and twin motor drives. Each roll is independently driven, ensuring even wear and efficient material processing. The design also includes features to prevent short-circuiting of oversize material and a continuous scraper assembly to avoid fines build-up.

Applications: Rolls Crushers are crucial in the mining, construction, and agriculture sectors for breaking down materials into smaller sizes for further processing.

MechProTech, an OEM of Comminution Solutions

The article highlights innovative equipment and comminution methods in industrial applications.

MechProTech’s contributions to this field, through our advanced crushing, grinding, and scrubbing solutions, emphasise our company’s position as a leader in the industry.

Contact us for more information on our mineral processing solutions.