Hydrometallurgy is a crucial metal extraction technique using chemical solutions to extract valuable metals from ores. This method stands out for its high efficiency and eco-friendliness. Moreover, it is a process that requires specialised equipment to ensure that the extracted metals are of high quality.

MechProTech embodies the advancement of hydrometallurgical equipment, from high-rate thickeners to mixers, in a seamless transition from ore to metal.

This article delves into the essential equipment behind hydrometallurgy, underlining their roles, effectiveness, and technological strides.

What is Hydrometallurgy?

Hydrometallurgy involves using chemical solutions to dissolve metals from their ores. This method is crucial in the worldwide effort to extract minerals sustainably.

The key to hydrometallurgy is using carefully designed equipment, including high-rate thickeners and advanced agitators. The choice of machinery significantly affects the effectiveness and environmental impact of the extraction process.

Selecting appropriate hydrometallurgical equipment is not merely a technical decision; it’s a commitment to operational efficiency and environmental stewardship. As the demand for metals continues to rise, driven by industries ranging from electronics to renewable energy, the importance of optimising the extraction process has never been more pronounced.

According to recent industry analyses, the global hydrometallurgy equipment market size is projected to expand significantly, with forecasts indicating the rising demand for metals as the industry shifts towards more sustainable and efficient extraction technologies.

Understanding the Role of High-Rate Thickeners

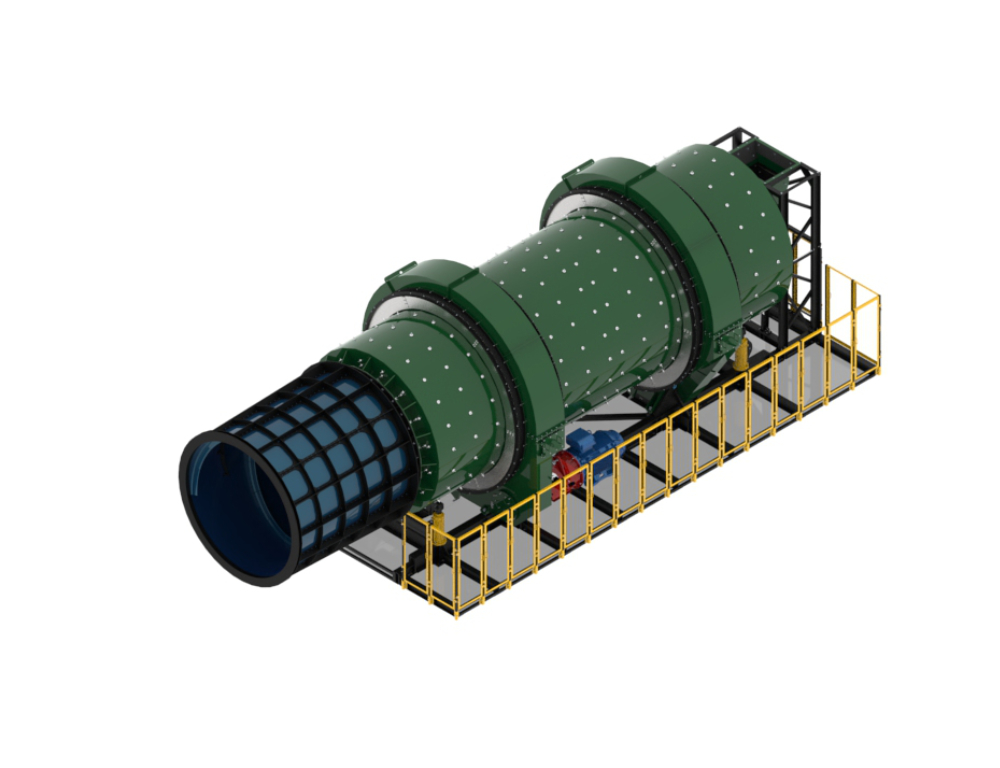

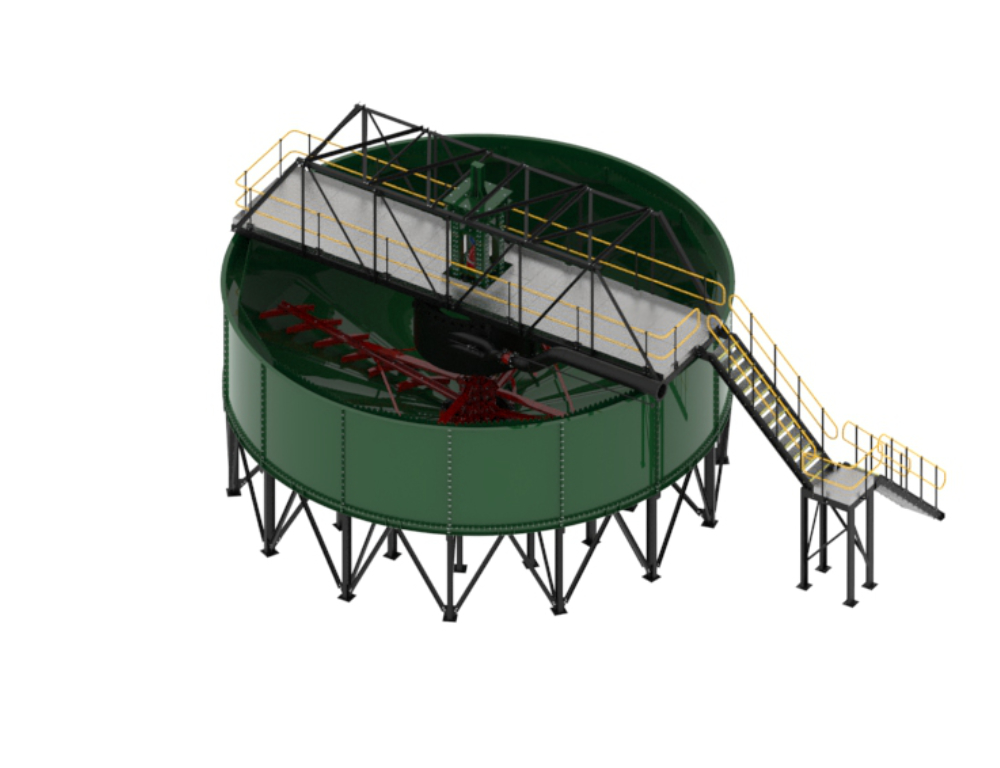

High-rate thickeners efficiently separate solids from liquids in mineral slurries, making their technology critical in hydrometallurgy. This separation is crucial for concentrating the ore and recycling water once separated, minimising the environmental impact.

High-rate thickeners are used to enable faster and more efficient clarification and thickening. They achieve this by accelerating particle settling using flocculants and optimising the tank’s design. In hydrometallurgy, it is critical that this process is efficient due to the precise handling of chemical solutions and the recovery of valuable metals at the core of operations.

MechProTech stands out in our design and optimisation of high-rate thickeners by focusing on custom solutions that cater to the specific needs of each mining operation. Our approach involves meticulously analysing the mineral composition and the operational requirements to engineer thickeners that meet and exceed performance expectations.

By integrating advanced materials, innovative tank designs, and state-of-the-art control systems, MechProTech ensures that our high-rate thickeners provide optimal efficiency, reliability, and sustainability in metal extraction processes. This customised engineering boosts operational efficiency for hydrometallurgy, reduces waste, and optimises water reuse, leading to significant cost savings and environmental benefits.

The Importance of Reagent Plants in Hydrometallurgy

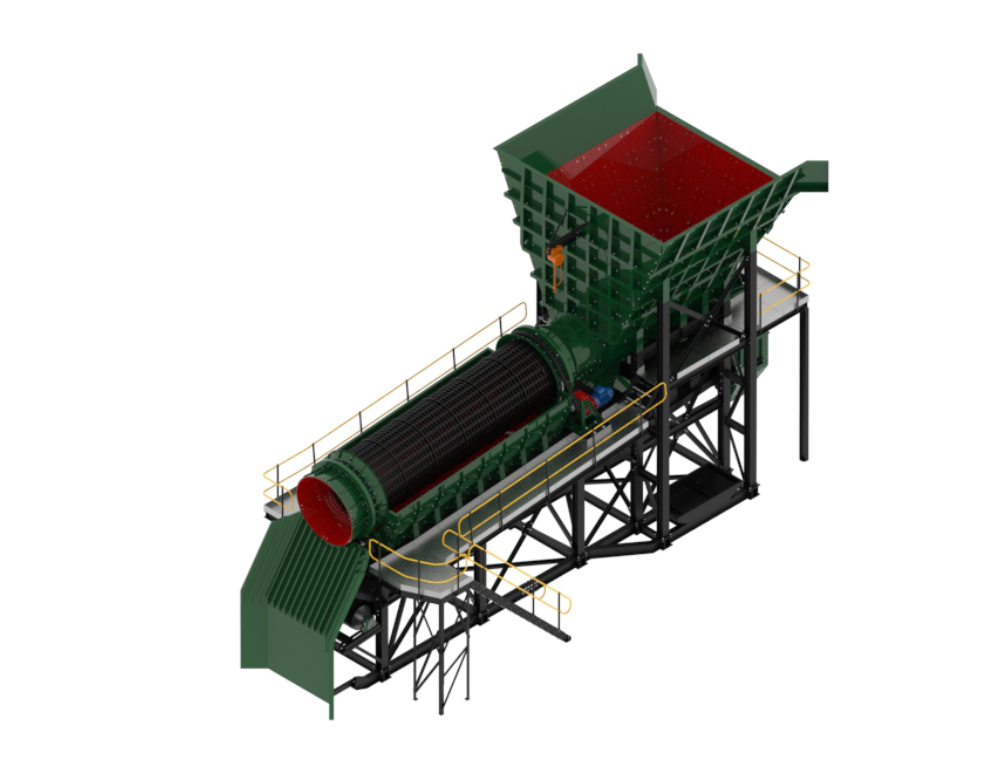

Reagent plants are facilities within the hydrometallurgical sector where chemical reagents are prepared, stored, and managed. These reagents serve as agents in deleting metals from ores. The precise formulation, handling, and application of these chemicals are crucial for optimising metal recovery, minimising waste, and ensuring the environmental sustainability of mining operations.

MechProTech’s systems are designed to accommodate the specific chemical requirements and operational challenges of each mine. By conducting thorough analyses of the mine’s ore composition and extraction processes, we can engineer reagent plants that ensure the optimal preparation, storage, and delivery of reagents, directly influencing the efficiency and effectiveness of the metal extraction process.

One of the standout features is the incorporation of automated dosing systems, which precisely control the amount of a chemical or chemicals introduced into the process, ensuring optimal reaction conditions and minimising the risk of human error.

Additionally, MechProTech integrates advanced monitoring and control technologies that allow for real-time adjustments and provide detailed analytics on reagent use and process efficiency. This enhances the operational performance of the hydrometallurgy process and significantly improves safety by reducing direct human exposure to hazardous chemicals.

Mixers and Agitators: Ensuring Homogeneous Solutions

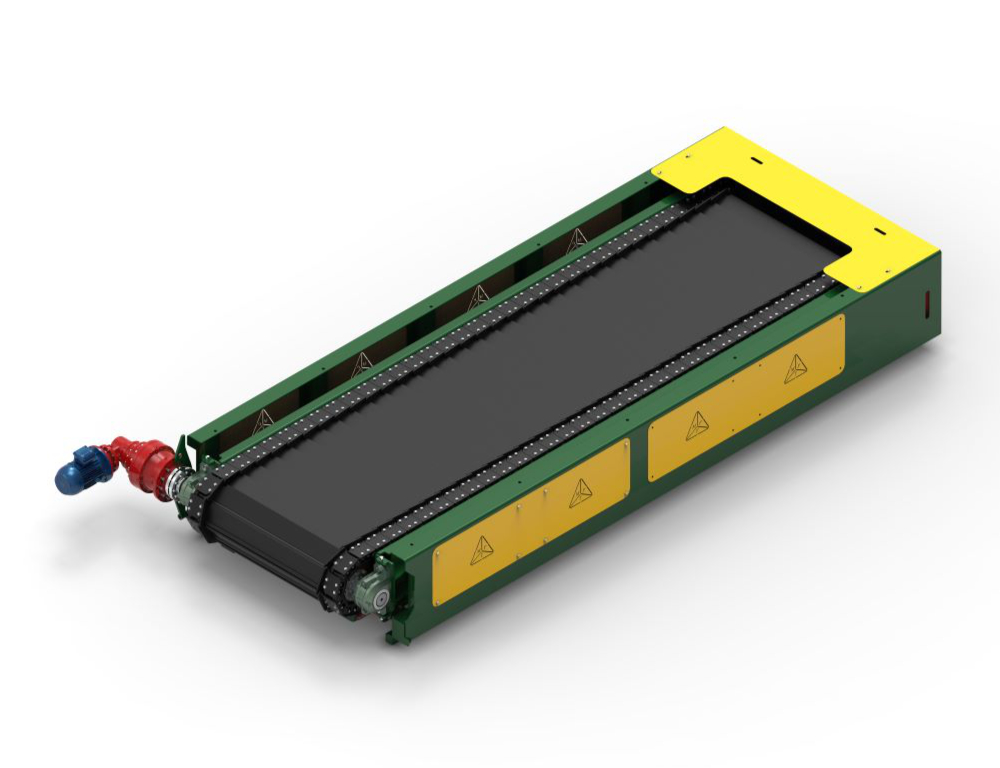

Mixers and agitators ensure the uniform mixing of solids and liquids essential for efficiently extracting metals. These devices facilitate the thorough integration of chemical reagents with ore slurries, a critical step for successfully dissolving valuable metals. The homogeneity of these mixtures directly impacts the reaction rates, metal recovery efficiencies, and overall process stability. Without the effective stirring action of mixers and agitators, the hydrometallurgy process could suffer from incomplete reactions, leading to lower metal yields and higher chemical consumption.

MechProTech’s mixers and agitators are designed to meet the diverse needs of the mining industry. Our product lineup includes everything from the basic mechanical agitators for basic mixing tasks to advanced, high-shear mixers for complex chemical reactions.

What sets MechProTech’s equipment apart is its adaptability to various mining and extraction scenarios. Recognising that each mining operation has unique requirements based on ore composition, chemical reagents, and process conditions, MechProTech designs its mixing solutions with flexibility in mind. This adaptability ensures optimal mixing performance, regardless of the specific challenges of different ores or extraction processes.

Metal Extraction with MechProTech

The metal extraction industry is undergoing a significant transformation due to advancements in hydrometallurgical equipment and processes.

MechProTech has consistently demonstrated our ability to develop equipment that can be efficient, sustainable, and cost-effective in metal extraction operations.

MechProTech’s Original Equipment Solutions:

- High-Rate Thickeners: Improving water recovery and efficiently separating solids from liquids.

- Reagent Plants: Automating dosing systems and real-time monitoring ensure precise chemical usage and enhanced safety and process efficiency.

- Mixers and Agitators: Adaptable and advanced mixers and agitators ensure optimal mixing conditions, improving metal recovery rates and reducing chemical waste.

- Innovations for Sustainability: Reducing energy consumption, minimising environmental impact, and leveraging automation for better resource management.

Environmental and Economic Impacts

The adoption of advanced hydrometallurgical equipment offers significant environmental and economic benefits. By enhancing process efficiency and reducing waste, companies can significantly lower their operational costs and environmental footprint.

MechProTech: Original Manufacturers of Hydrometallurgy Equipment

For mining operations looking to navigate today’s challenges, choosing an equipment partner is more critical than ever. MechProTech stands ready to lead the way with its suite of hydrometallurgical equipment and solutions designed to meet the demands of efficiency, sustainability, and economic viability.

Whether you’re looking to optimise existing processes or embark on new mining ventures, MechProTech offers the expertise, technology, and support to ensure your success.

Explore MechProTech’s innovative solutions and discover how they can transform your hydrometallurgy operations.