The importance of efficient material sorting and classification cannot be overstated. As a critical component of numerous industrial processes, from mining to recycling, effectively separating and categorising materials is essential to operational success.

Referring to Mineral Processing, Classification follows Comminution, the mechanical process of breaking down large solid materials into smaller particles.

This article delves into the world of classification, exploring the various sorting techniques and equipment essential for modern industries, including the mineral processing industry.

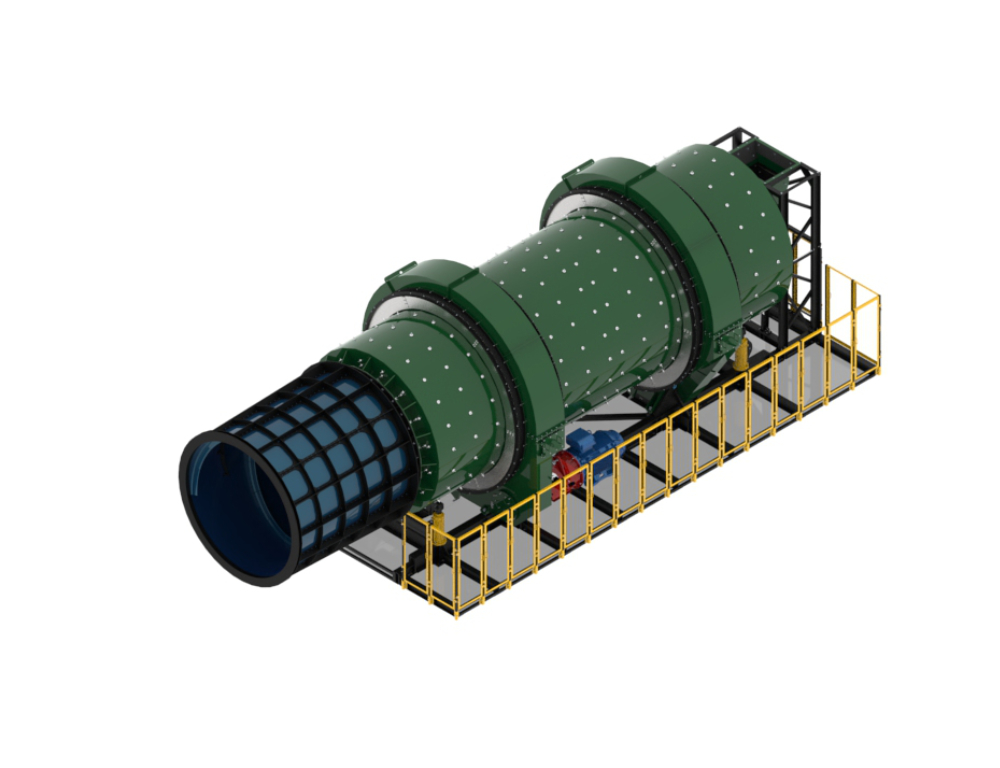

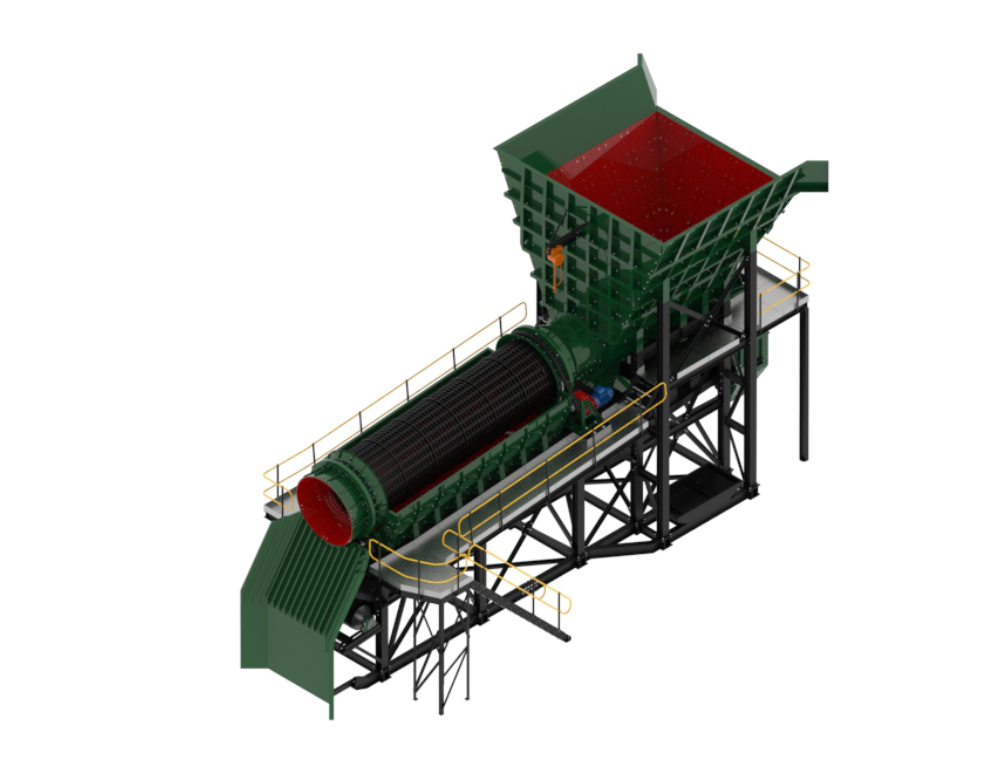

Furthermore, this article will examine the mechanics behind popular equipment such as rotating barrel screens, rotating barrel breakers and static and vibrating screens, highlighting the innovative solutions offered at MechProTech.

Overview of Classification in Industrial Processes

Classification is an essential aspect of industrial processes as it involves sorting and segregating materials or products based on their properties or characteristics.

This process can be done manually or with the help of automated systems.

The main goal of classification is to optimise the production process by ensuring that each material or product is directed to the appropriate production stage. Efficient material separation and handling in heavy-duty industrial processes rely heavily on accurate classification.

For example, in the food industry, classification separates raw materials based on their size, shape, weight, or quality. The pharmaceutical industry uses classification to sort drugs based on their dosage form, strength, and therapeutic category. In the mineral processing industry, classification segregates minerals based on their composition or physical properties.

Overall, classification plays a crucial role in ensuring efficiency and effectiveness. It is designed to identify and separate the desired product, help to minimise waste, reduce production time, and improve the quality of products.

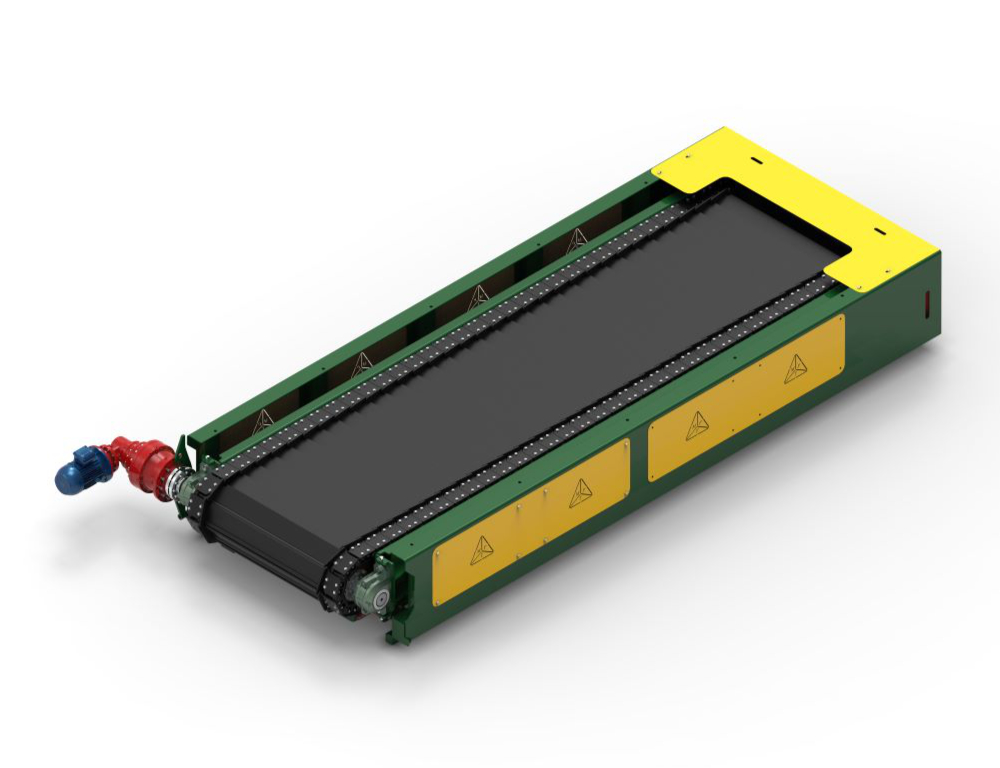

Critical Sorting Equipment and Applications

Several sorting techniques are employed in industries, each tailored to specific material characteristics and process requirements.

Classification Equipment

- They are used extensively for their efficiency in separating larger particles.

- These screens are renowned for their proficiency in segregating larger particles. They are particularly beneficial in scenarios where precision and durability are of the essence.

- Effective for breaking down and classifying materials in a single step, ensuring a seamless process flow.

- Offer dual functionality of breaking down materials and classifying them simultaneously; these breakers streamline the process flow and enhance efficiency.

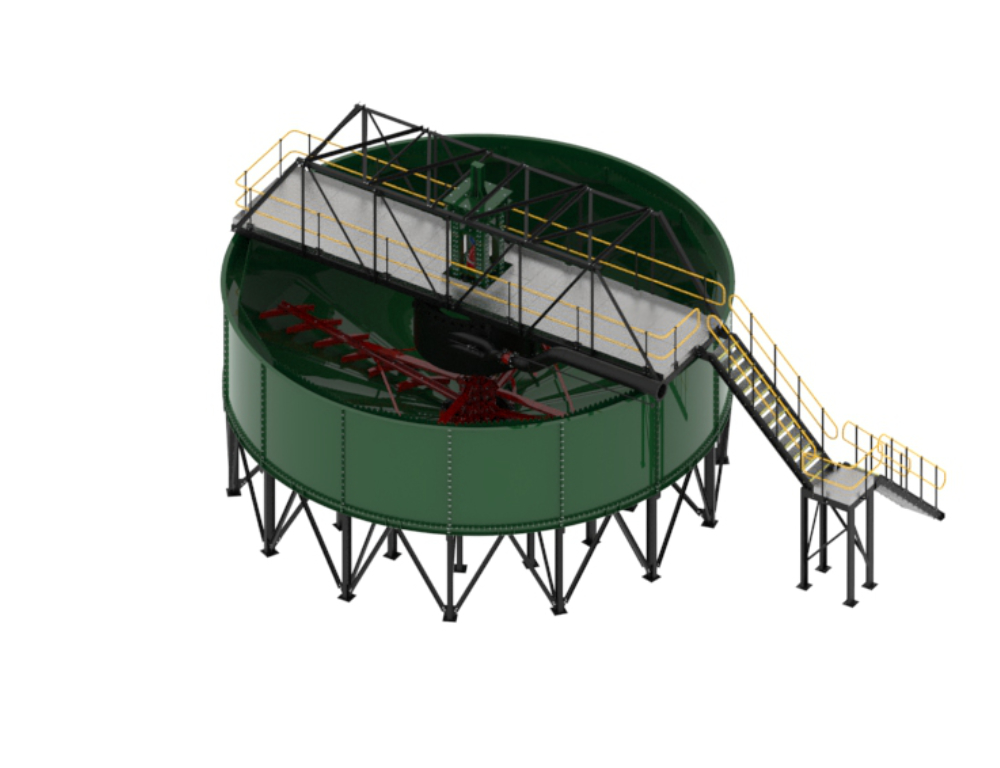

Vibrating screens and static screens represent other vital classification methods.

- With their ability to handle various materials and sizes, vibration screens are suitable for multiple industrial applications.

- On the other hand, static screens are preferred for their low-maintenance and energy-efficient operation, particularly in industries where water conservation is critical.

Innovative Equipment in Material Classification

Advancements in classification equipment focus on enhancing accuracy, reducing operational costs, and improving environmental sustainability.

These advancements aim to provide businesses with more efficient and effective ways to classify and sort materials, products, and other items. By reducing the need for manual labour and increasing the speed and accuracy of classification processes, these technologies can help businesses save time and money and reduce their environmental impact.

MechProTech is at the forefront of these developments, offering reputable vibrating and static screens. These screens are designed for high performance and cater to the evolving needs of the mining and mineral processing industry, emphasising efficiency.

Optimising Performance

Best Practices in Equipment Usage

Regular maintenance and correct operation are essential to maximise the benefits of classification equipment like rotating barrel screens and breakers.

This includes but is not limited to the following:

- Routine inspections

- Timely replacement of worn parts

- Adherence to the manufacturer’s operational guidelines.

Training personnel in adequately handling these machines can significantly enhance their lifespan and performance.

Future Trends in Sorting Technology and its Impact on Industries

The future of classification technology points towards automation, AI integration, and sustainable practices.

With the rapid technological advancements in various industries, the need for more effective, efficient and sustainable solutions is becoming increasingly important. Sorting solutions that are smarter and more energy-efficient are in high demand. In South Africa, this is partly due to our energy crisis. Additionally, businesses seek to reduce their environmental impact while increasing efficiency.

These solutions can help businesses reduce their energy demand, costs, and impact while maintaining their operations and productivity.

MechProTech as an OEM of Classification Equipment

Understanding the various sorting techniques and equipment, such as those offered here at MechProTech, is crucial for industries reliant on efficient material classification.

By staying on top of technological advancements and best practices, businesses can ensure optimal performance and sustainability in their operations.

Consider MechProTech as your mining and process equipment provider.