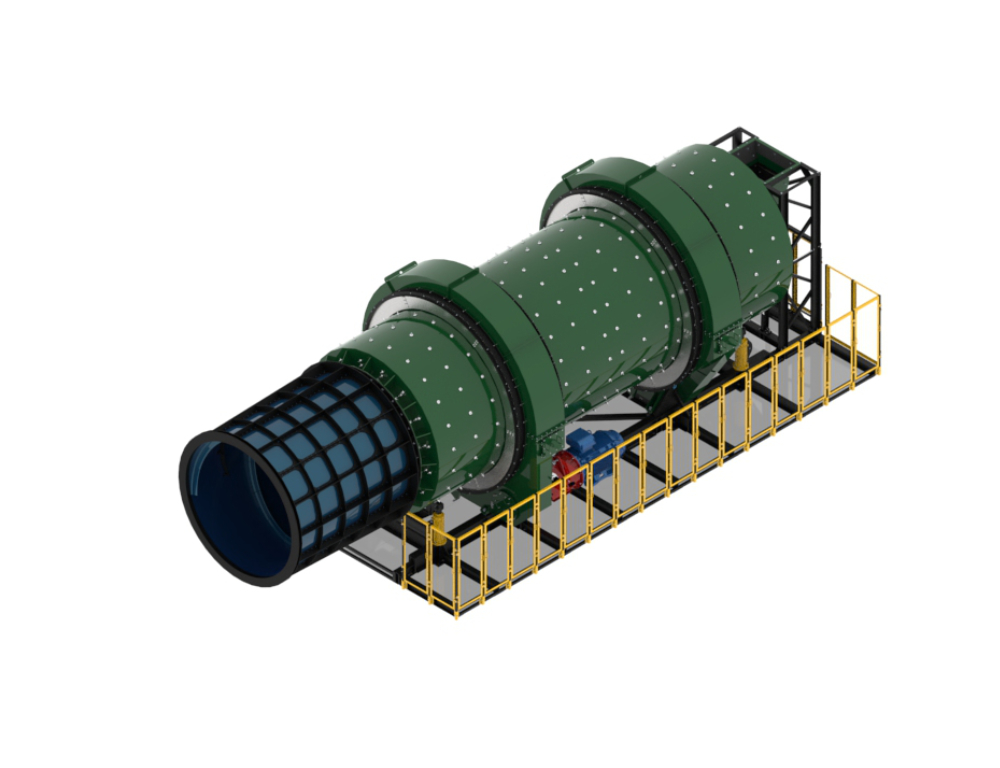

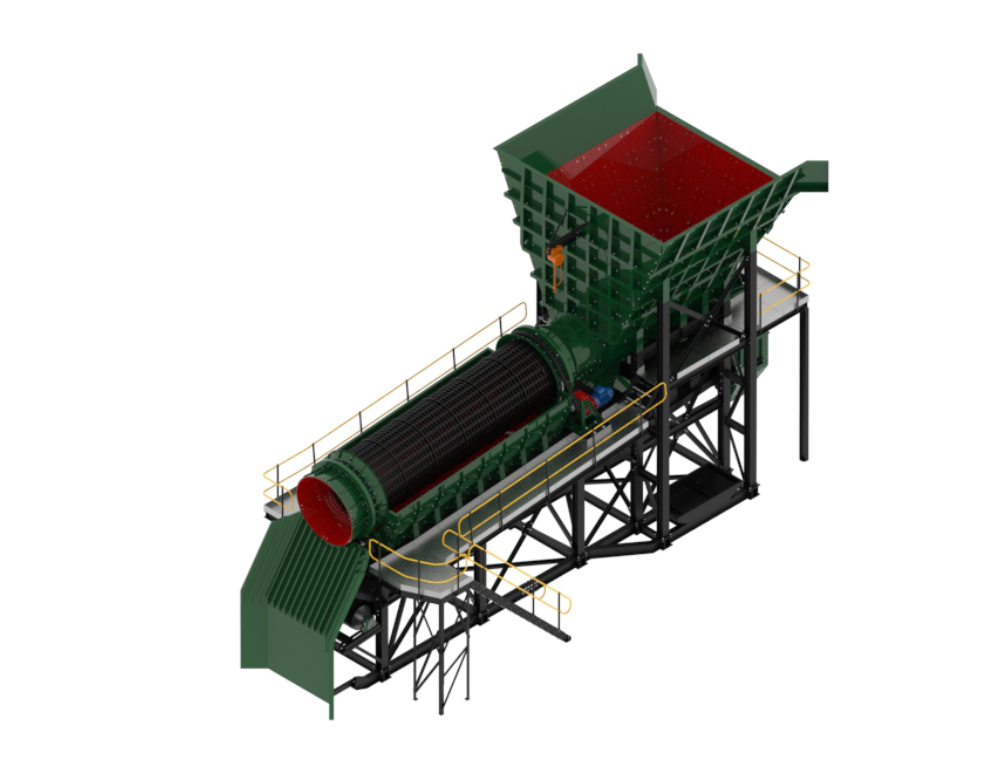

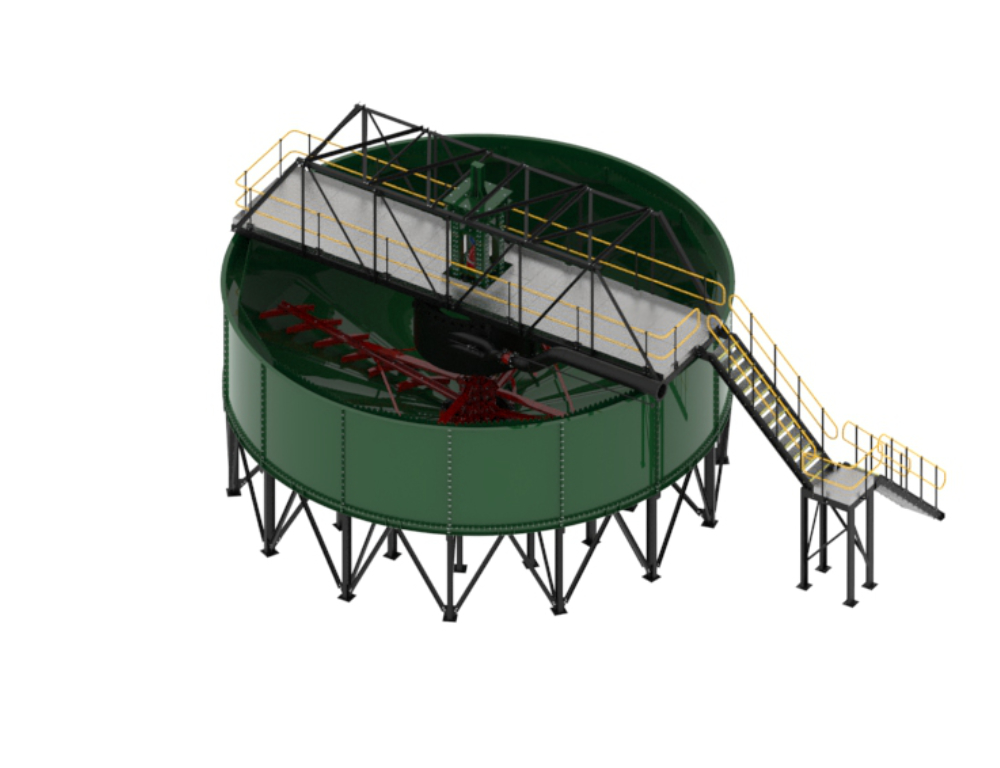

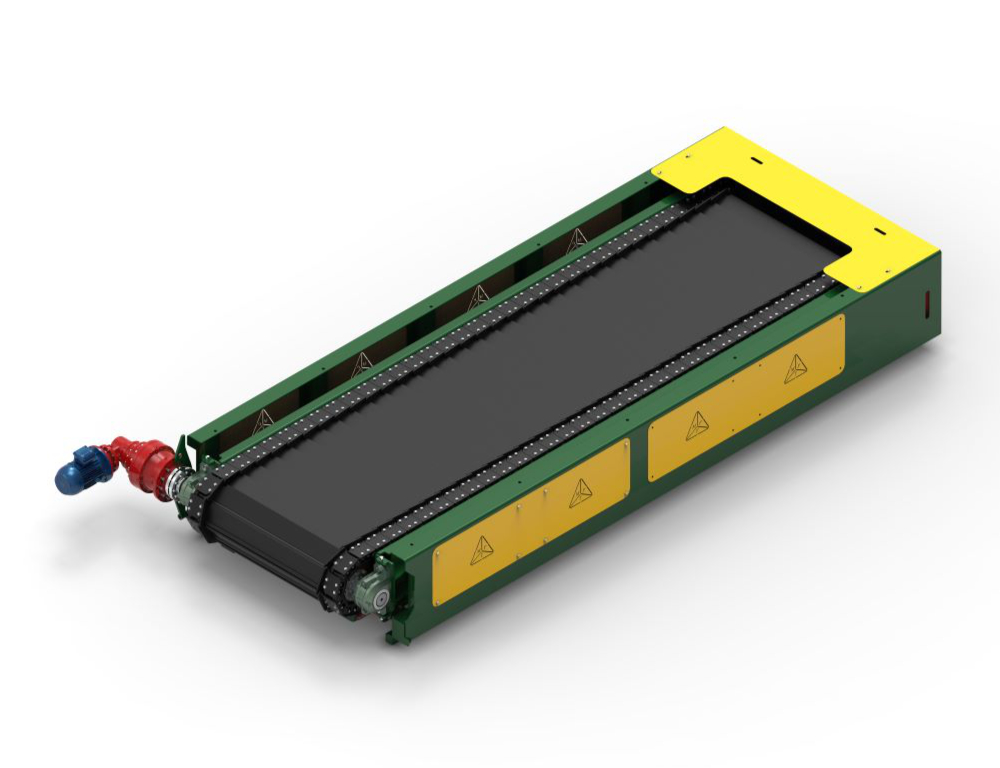

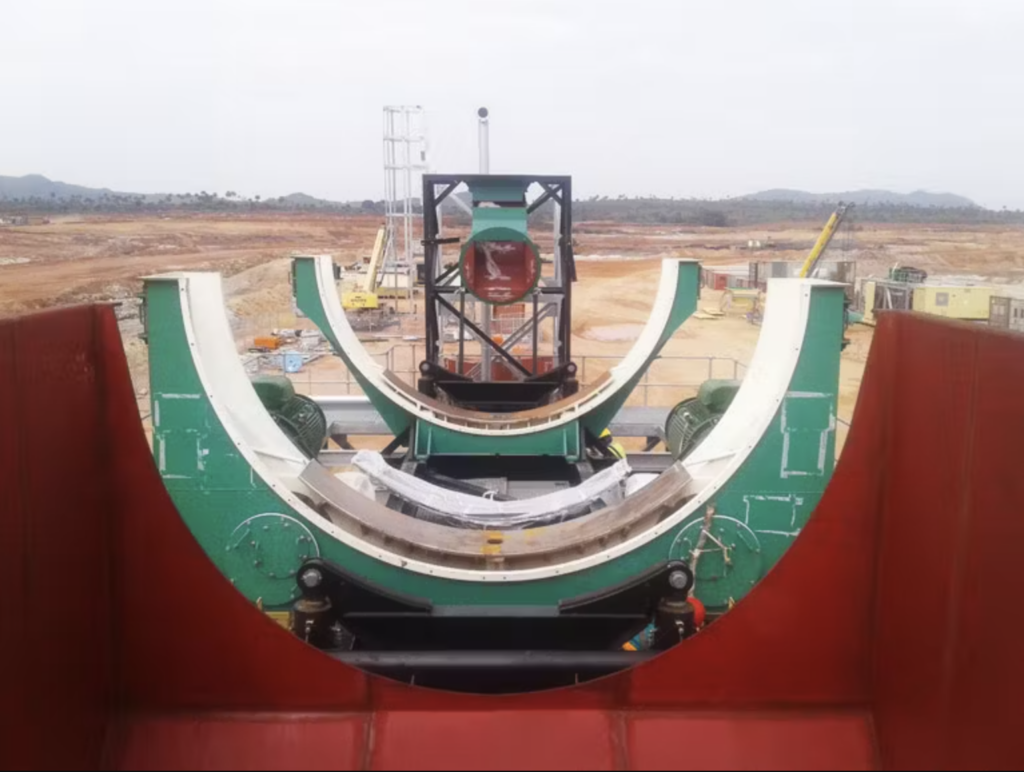

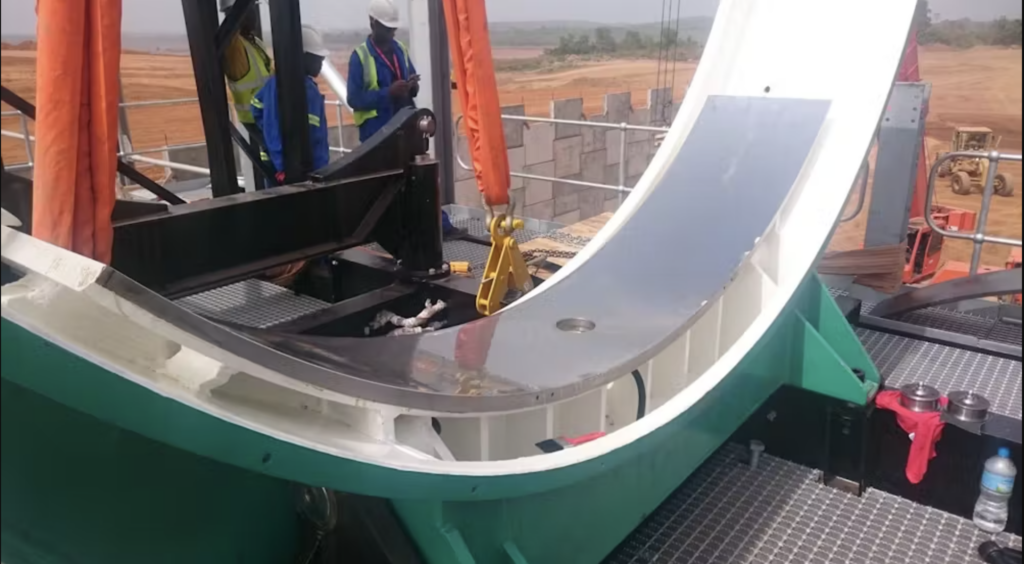

It’s hard to imagine an industry more harsh or demanding on bearings than the mining industry. Heavy loads always in motion, vibrations all the time, and the ever-present dirt, dust, and debris. That’s why MechProTech, a company that designs and manufatures mineral processing equipment, recently introduced hydrodynamic composite bearings. They are made out of Vesconite, a proprietary engineering thermopolymer, and shaped into curved half- or quarter-moon plate shapes. The bearings support round-bottomed conveyors on its mills, which fine grind mineral ore, and scrubbers, which wash and disperse clays and agglomerated material made up of fines and superfines.

According to MechProTech Sales Manager Wynand Boshoff, the bearings run on an oil film, so there is no surface contact between the bearing and the outside supports for the mills and the scrubbers, and energy-consuming friction or wear during operation is minimal. Oil is pumped into the bearings by a dedicated supply line. If the oil supply malfunctions or breaks down, the mill or scrubber is automatically shut down.

“Vesconite is a sacrificial bearing that provides support. And if the oil the bearings run on breaks down, there might be some damage to the bearings, but not to our more-costly equipment,” says Boshoff.

MechProTech notes that the Vesconite bearings cost less for this application than white metal bearings, which can be six times more expensive than the thermopolymer bearings. (White metals are light-colored metal alloys, typically lead or tin based, used in many applications such as bearings, jewellery, a base for plated silverware, and fusible plugs.) As a bearing material they offer extended service lives under normal operating conditions.

The oil-lubricated Vesconite bearings are also hard-wearing and grease-free, so they require little maintenance, which is a major plus in an industry in which machinery downtime is costly. They are also lighter and more maintenance friendly than white-metal bearings in that they can be replaced more quickly and easily. White metal bearings need a complex babbit (housing) to form the bearing’s support structure, and the babbit must be broken down and rebuilt when replacing the bearings.