South Africa has relied on its vast mineral wealth for over a century. The country’s geological landscape is particularly suited for mining, providing a rich variety of mineral resources that have played a significant role in its past and will continue to shape its future.

In this article, we aim to introduce our readers to the world of mineral processing.

Join MechProTech, the company making waves in South Africa’s mineral processing industry as a leading equipment manufacturer and global supplier. We hope to offer insights and information to help you better understand this field.

Overview of South Africa’s Mineral Wealth:

South Africa is abundantly blessed with diverse minerals, which make it one of the leading mining nations in the world. The industry is a significant contributor to the country’s economy as well as the global economy.

Investment in Mining and Minerals

Investors from all over the world are drawn to South Africa’s mineral resources, with many local and international companies exploring the potential of the country’s mining industry. The South African government has also created favourable policies for investors, making investing in the sector easier.

The industry provides employment opportunities for millions of people and generates significant revenue for both the country and its foreign investors.

With a focus on sustainable mining practices, South Africa is poised to continue its success in the mining industry for many years.

Core Function of Mineral Processing

Mineral processing is a multidisciplinary field that involves extracting, refining, and processing minerals from ore to produce useful and valuable products.

Companies in this sector use advanced techniques, such as mineral separation, to extract minerals from ores. The ores are then further processed through various methods, such as crushing, grinding, and sorting, to unlock the full potential of their mineral reserves.

More Than the Process

The mineral products processed by the industry include precious metals, base metals, industrial minerals, and energy minerals. The journey from underground deposits to finished products requires a combination of human ingenuity and engineering excellence.

The mineral processing industry’s products are used in various industries and sectors, including construction, manufacturing, energy production, and agriculture, among others.

As a result, the sector plays a prominent role in the global economy.

Environmental and Regulatory Compliance:

The mineral processing industry’s growth comes with a significant environmental impact, so regulatory bodies impose strict laws and regulations to minimise the negative impact of mineral processing operations on the environment.

General Regulations Followed

In South Africa, mineral processing companies are required to adhere to a comprehensive set of regulations that cover various aspects of their operations.

The following are a few of the general regulations followed:

- Mineral and Petroleum Resources Development Act (MPRDA): Establishes the regulatory framework for the mining industry, including mineral processing.

- National Environmental Management Act (NEMA): Sets out the requirements for environmental authorisations and permits.

- Mine Health and Safety Act (MHSA): Set regulations and standards to prevent accidents and promote safe working conditions.

- Occupational Health and Safety Act (OHSA) Sets standards for protecting employees’ health and safety.

- National Water Act: This act governs water resource management in South Africa, including provisions related to water licenses and permits.

- National Environmental Management: Air Quality Act: Regulates air quality and emissions from industrial activities and standards for emissions control and requires permits for air quality impacts.

- South African Bureau of Standards (SABS): Develops and maintains national standards, including those related to mineral processing equipment, safety, and quality control.

- Various provincial and local regulations: In addition, provincial and municipal regulations may apply to mineral processing activities, such as zoning and land-use regulations.

Companies in the sector increasingly adopt eco-friendly practices and sustainable technologies to comply with these regulations.

In trying to find the balance between economic and environmental impact, the industry is committed to addressing this challenge by adopting sustainable practices, investing in technology and innovation, and collaborating with relevant stakeholders to find solutions.

Technological Advancements in Mineral Processing:

With innovative extraction and processing methods, the industry has seen a significant improvement in efficiency and sustainability.

These advancements have improved the quality of the end product and helped mitigate the environmental impact of mineral processing operations.

-

- Automated sorting systems sort minerals based on their physical properties, making the process more efficient and reducing the need for manual labour.

-

- Advanced mineral separation techniques have been developed to separate minerals that were previously impossible to separate. These techniques have helped increase the yield of valuable minerals and have reduced the amount of waste produced during the process.

These technological advancements in the mineral processing industry have significantly impacted the economy and the environment. They have enabled the industry to produce more minerals using less energy and resources and have helped create a safer working environment for industry workers.

MechProTech is a reputable manufacturer and supplier of equipment in the mineral mining and processing industry.

MechProTech’s Advanced Products and Services

We strive to uphold the highest quality standards, focusing on designing and manufacturing mining and mineral processing equipment.

The Mineral Processing Process comprises different phases. The comminution phase, the classification phase, the hydrometallurgy phase and the material and handling phase. All of these then come together as a part of the pilot plant.

Our MPT Equipment Range:

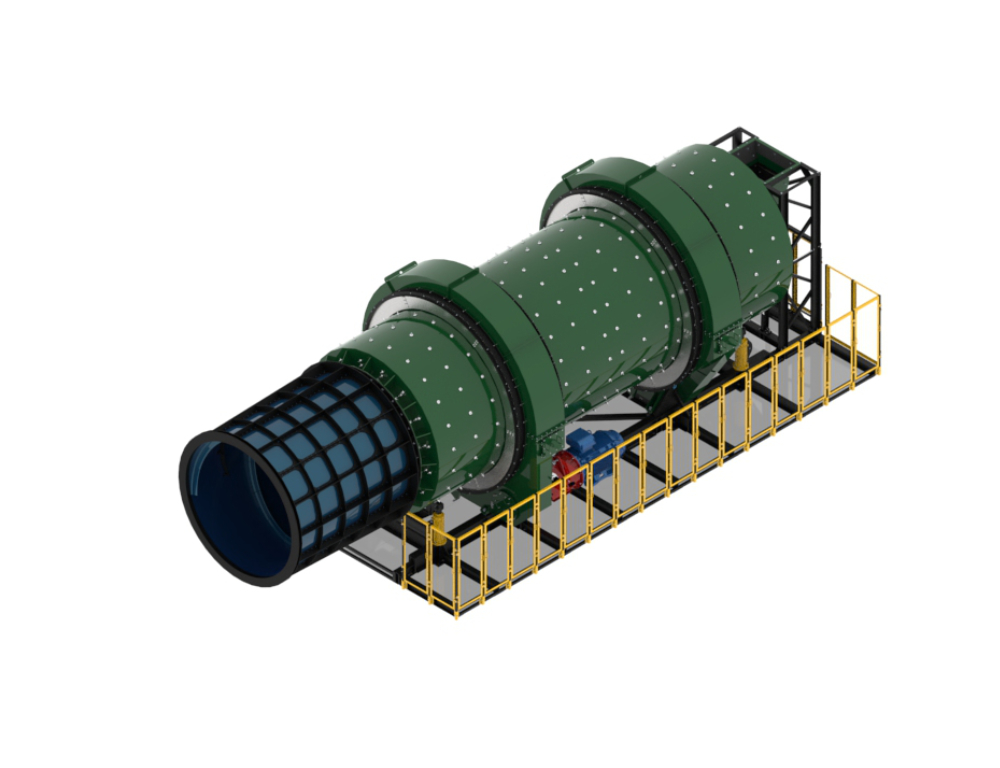

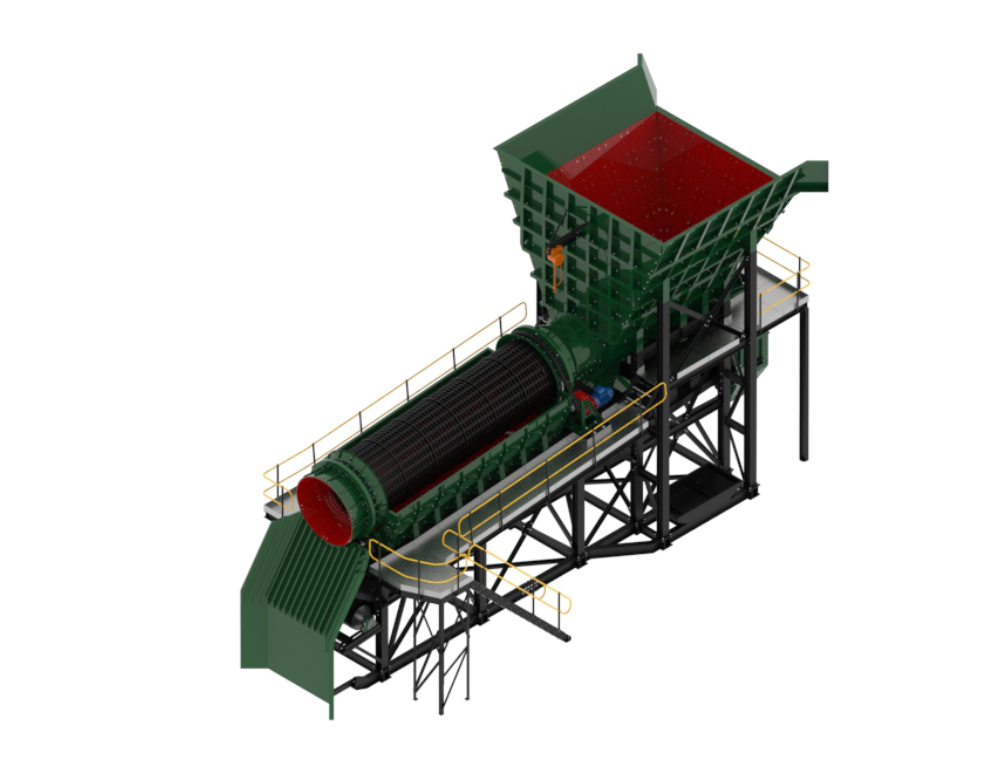

Comminution:

A process of crushing ore particles to extract minerals.

Classification:

A method of separating minerals into different products based on particle velocity in a fluid medium.

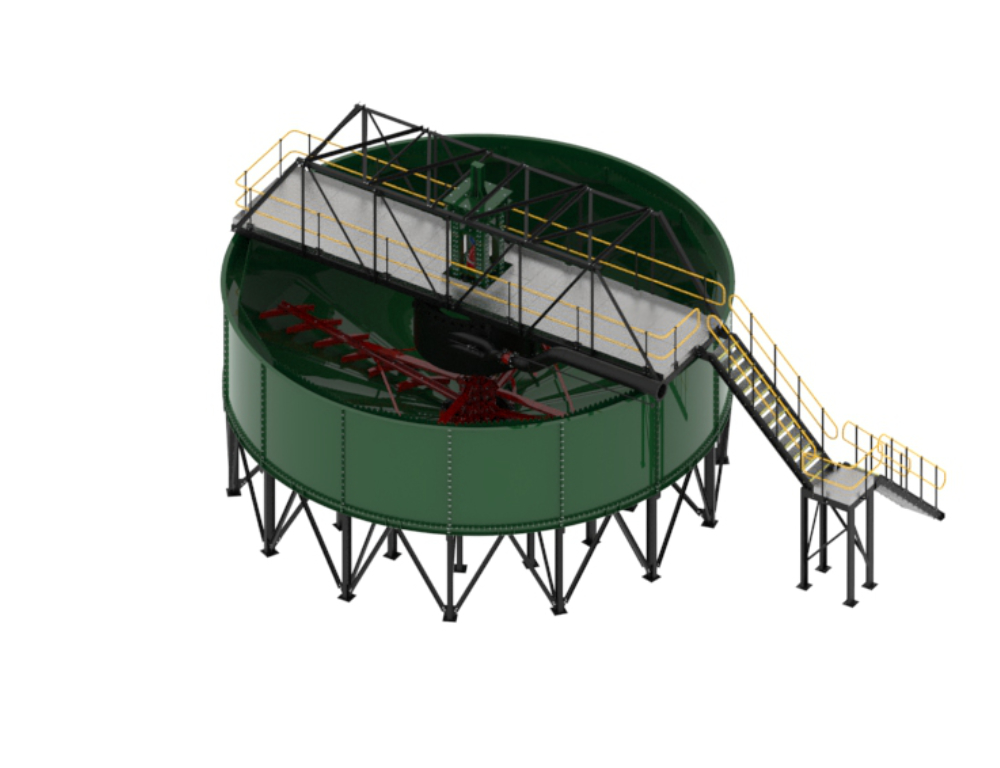

Hydrometallurgy:

This technique employs aqueous solutions to extract metals from ores, concentrates, and recycled materials.

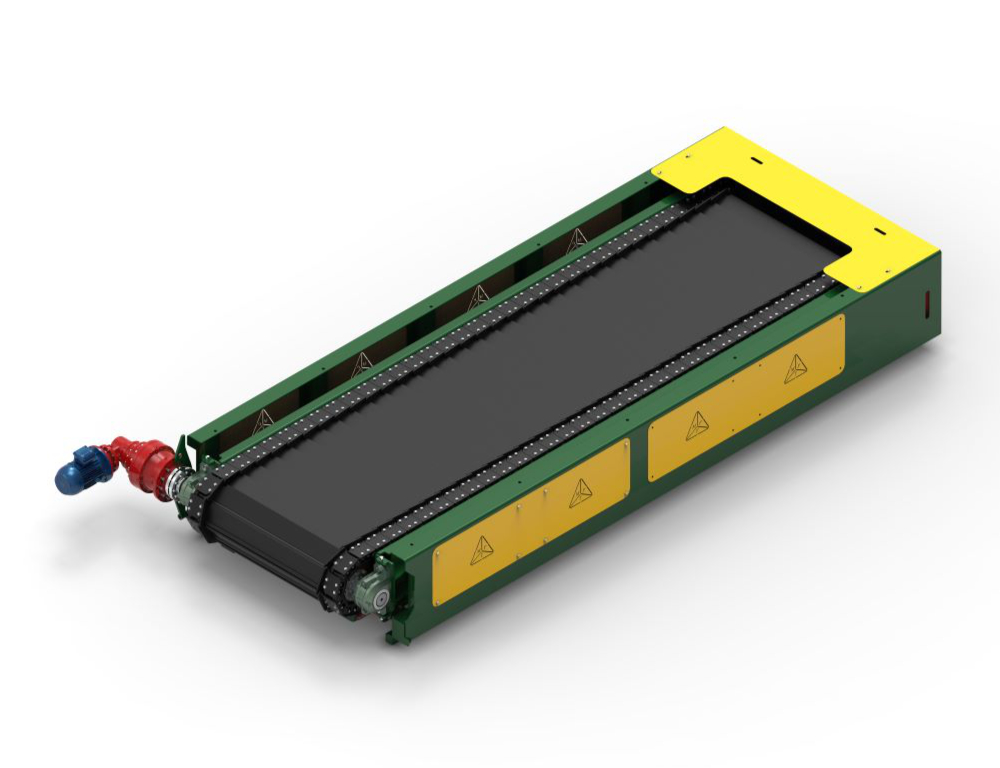

Materials and Handling:

This section aids in steady material flow throughout the process.

Pilot Plants:

All of MechProTech’s equipment is expertly designed and sized to meet the metallurgical processing requirements of all commodities found in the mining and minerals sector. With the advantage of an extensive fabrication, machining & assembly facility, we reduce on-site risk by fully assembling & test running all equipment in-house.

Making Waves in the Mineral Processing Sector

The mineral processing industry in South Africa is poised to face both opportunities and challenges. The sector must progress by adopting sustainable practices, embracing technological innovation, and practising responsible resource management.

MechProTech, based in Benoni, South Africa, is a beacon of innovation and excellence in this evolving landscape. Whether you seek advanced mineral processing equipment, solutions or expert advice, we are your go-to company.

Visit us at MechProTech to discover how we can work together to harness mineral wealth responsibly and innovatively.